Have you ever wanted to put a cool design on your clothes or accessories, but wondered if it would stay looking bright and vibrant after lots of washes?

There’s a special printing method called sublimation that can give you long-lasting, full-color designs on fabric. But can you use it on any kind of fabric, like the soft and flowy viscose material?

In this article, we’re going to explore ‘Can you sublimate on viscose?’. Sublimation printing is a bit different from regular printing, so some fabrics might not work well with it.

You’ll learn about other fabric options that are ideal for getting amazing sublimated designs. We’ll also share useful tips on how to get the best results if you do decide to sublimate on a viscose blend fabric.

So, keep reading!

you may also like:

- Why Sublimation Black Looks Grey And How To Solve It?

- What Is Sublimation Glass? (Features & Process)

- Butcher Paper vs Parchment Paper For Sublimation

- How Many Prints Per Sublimation Cartridge Can You Get?

Can You Sublimate on Viscose?

The short answer is: No, you cannot sublimate on pure viscose fabric.

Viscose, also known as rayon, is a natural fiber derived from cellulose. While it has a beautiful drape and feels soft against the skin, it’s not suitable for sublimation printing on its own.

Here’s an in-depth explanation of why you can’t sublimate on pure viscose:

- Sublimation requires high heat: The sublimation process involves transferring a design from special ink onto fabric using intense heat. This heat causes the ink to turn into a gas that bonds with the fibers of the fabric.

- Viscose melts at high temperatures: Unlike synthetic fibers like polyester, viscose has a relatively low melting point. At the high temperatures used in sublimation (around 400°F or 204°C), viscose can melt and damage the print.

If you attempt to sublimate on pure viscose, the intense heat required for the process would cause the fabric to melt, distort, and potentially catch fire.

The fabric simply can’t withstand the high temperatures needed for the ink to turn into a gas and bond with the fibers.

Attempting to sublimate on pure viscose would result in a melted, distorted mess, ruining both the fabric and the design you were trying to transfer.

How to Sublimate on Viscose

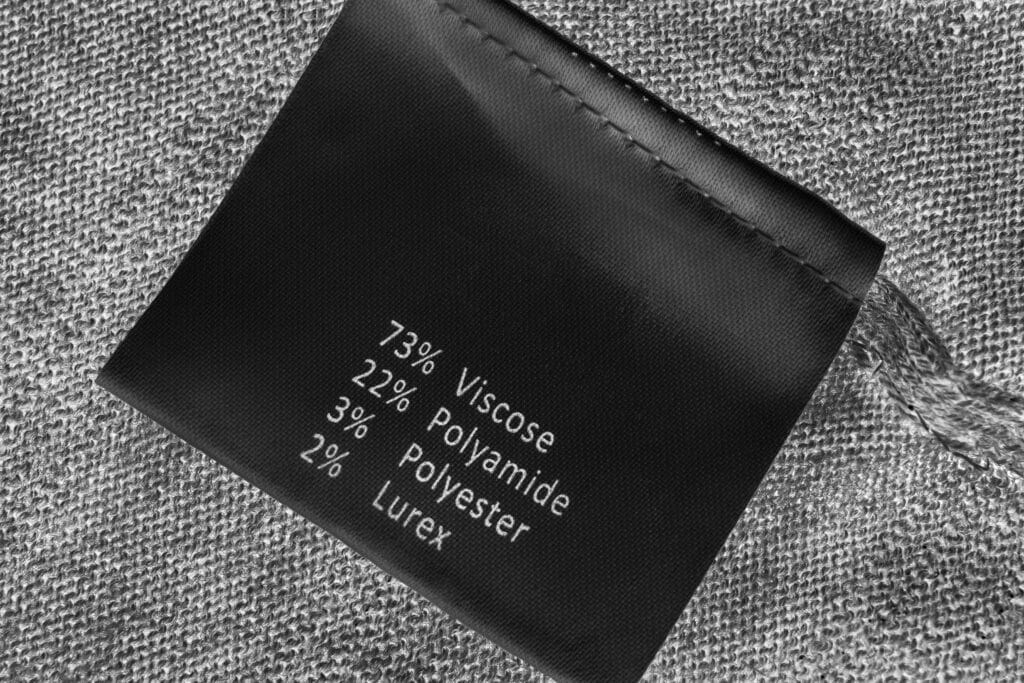

While you can’t sublimate on pure viscose, there are ways to achieve vibrant, long-lasting prints on fabrics that contain a blend of viscose and other materials.

Here are two popular options:

Polyester Blends

One popular option is to use a fabric that combines viscose with polyester. Polyester is a synthetic fiber that can withstand the high temperatures required for sublimation printing.

Unlike viscose, polyester has a much higher melting point, making it suitable for the intense heat used in the sublimation process.

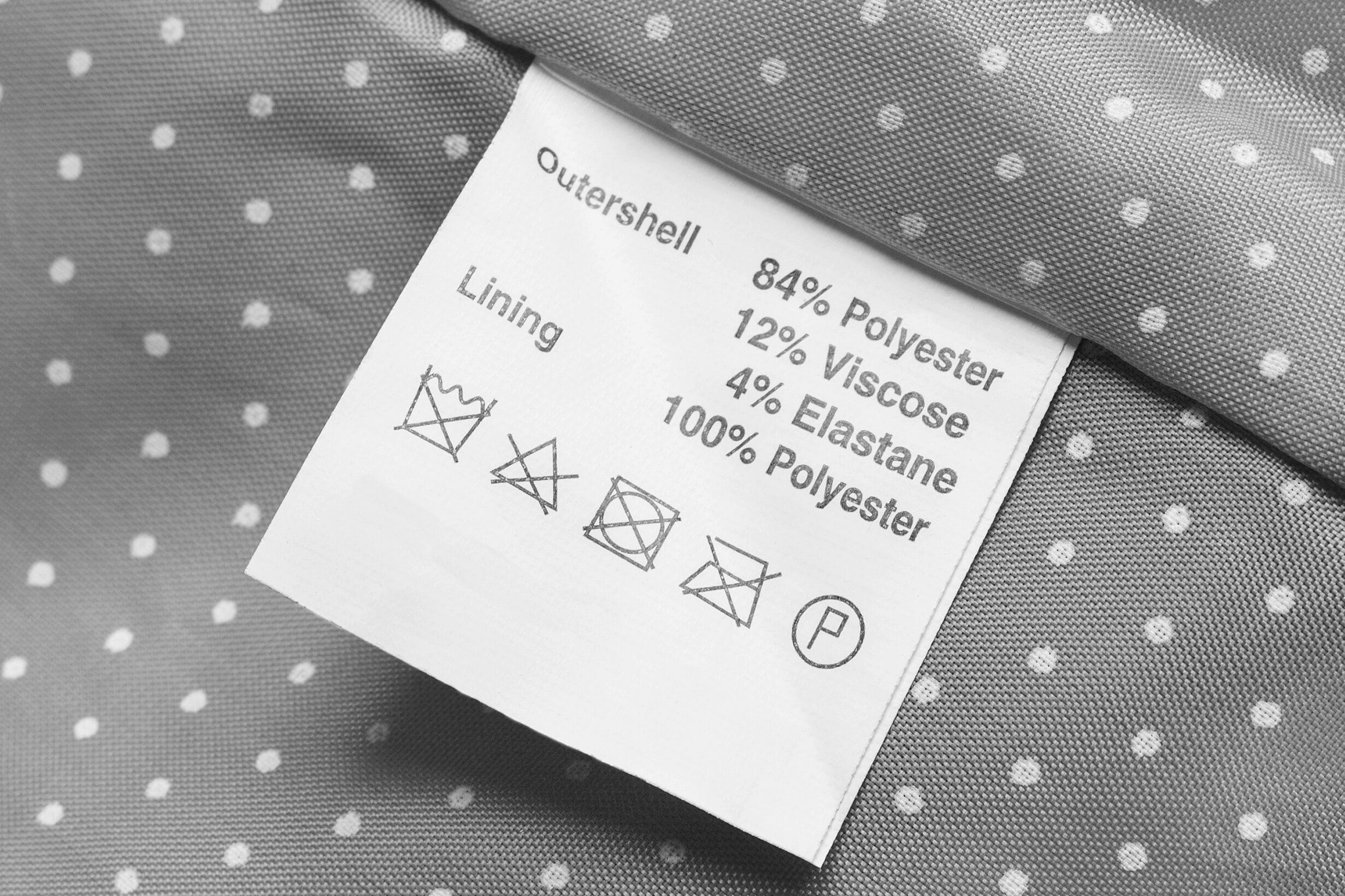

If the viscose content is low (around 30%) and the polyester content is high (around 70%), sublimation might be possible. However, it’s important to note that the results might not be as vibrant or long-lasting as on pure polyester fabrics.

For example, the BELLA+CANVAS 3880 Unisex Viscose Fashion Tee, which is 65% polyester and 35% viscose, is suitable for sublimation printing.

Poly-viscose Fabrics

Some manufacturers offer specifically designed poly-viscose fabrics that are suitable for sublimation. These fabrics typically have a higher polyester content than standard viscose blends, making them more suitable for sublimation.

The polyester component provides the heat resistance and durability needed for sublimation printing, while the viscose component adds softness, drape, and breathability to the fabric.

When using poly-viscose fabrics for sublimation, it’s crucial to follow the manufacturer’s recommendations for temperature and pressure settings, as these can vary depending on the specific blend and construction of the fabric.

Tips for Successfully Sublimating on Viscose

If you decide to sublimate on a viscose blend or poly-viscose fabric, here are some tips to help you achieve the best results:

1. Use the Right Temperature and Pressure

Follow the manufacturer’s recommendations for temperature and pressure settings when using a heat press.

Too much heat or pressure can damage the fabric or cause the print to distort. Excessive heat can cause the viscose fibers in the blend to melt or discolor, while too much pressure can crush the fabric and affect the print quality.

It’s generally recommended to use lower temperatures and shorter press times when working with viscose blends or poly-viscose fabrics, compared to pure polyester.

2. Invest in High-Quality Sublimation Paper

Not all sublimation transfer papers are created equal. Invest in high-quality paper designed for use with polyester blends to ensure vibrant, long-lasting prints.

Cheap or low-quality transfer paper may not produce consistent results or may not adhere properly to the fabric during the sublimation process.

Look for transfer papers specifically designed for use with blended fabrics, as these are formulated to work with the unique properties of the fiber blend.

3. Pre-Press the Fabric

Before transferring the design, pre-press the fabric to remove any moisture or wrinkles.

This will help the paint adhere better and prevent distortion. Moisture trapped in the fabric can cause the ink to bleed or spread during the sublimation process, resulting in a blurry or distorted print.

Pre-pressing the fabric also helps to flatten any wrinkles or creases, ensuring that the surface is smooth and even. This will help the transfer paper and heat press make full contact with the fabric, resulting in a more consistent and accurate print transfer.

4. Test on a Sample First

Before printing a large batch, test the sublimation process on a small sample of the fabric. This will help you identify any potential issues and adjust your settings accordingly.

Testing on a sample is especially important when working with viscose blends or poly-viscose fabrics, as the properties of these fabrics can vary depending on the specific blend and construction.

By testing on a small sample, you can ensure that the fabric can withstand the heat and pressure required for sublimation without melting, distorting, or discoloring.

5. Handle with Care

After sublimating, handle the printed fabric with care to prevent the design from cracking or peeling. Avoid excessive stretching or folding until the print has fully set.

The viscose component of the fabric blend can be more delicate than pure polyester, so it’s important to handle the printed fabric gently to avoid damaging the design.

It’s generally recommended to allow the printed fabric to cool completely before handling or folding it. This will give the ink time to fully set and bond with the fibers, ensuring a durable and long-lasting print.

By following these tips and using the right fabric blends, you can create beautiful, long-lasting prints on viscose-containing garments using the sublimation printing process.

Frequently asked questions

Below are a few frequently asked questions to help you out:

What type of fabric can you sublimate on?

Sublimation printing works best on synthetic fibers like polyester, nylon, and acrylic. These fibers can withstand the high temperatures required for the sublimation process and allow the ink to bond with the fabric at a molecular level.

Can you heat-press viscose?

While you cannot sublimate on pure viscose, you can heat press it for other purposes, such as applying heat transfer vinyl or foil designs.

However, you must use lower temperatures and shorter press times to avoid damaging the fabric.

Can you sublimate on all polyester?

Yes, you can sublimate on most types of polyester fabrics, including 100% polyester and polyester blends with a high polyester content. Polyester is the ideal fabric for sublimation printing because it can withstand the high temperatures required for the process.

Wrapping Up

Sublimation printing is a fantastic way to create vibrant, long-lasting designs on fabric, but it’s important to choose the right material.

While pure viscose is not suitable for sublimation due to its low melting point, you can achieve stunning results on viscose blends or poly-viscose fabrics designed specifically for this process.

By following the tips outlined in this article and investing in high-quality materials, you can unleash your creativity and bring your designs to life on viscose-containing garments.

Remember, always check the fabric content and test on a sample before embarking on a large project. With the right approach, you can create beautiful, vibrant prints that will stand the test of time.