Have you ever spent time carefully designing a beautiful black graphic or pattern, only to have it come out looking dull and grayish after sublimation printing?

It can be frustrating when your rich, vibrant blacks turn into a washed-out shade of gray.

But don’t worry, you’re not alone!

This is a common issue that many sublimation faces, and in this article, we’ll explore ‘Why sublimation black looks grey and how to solve it’. This article will help you achieve that deep, intense black print you’ve been aiming for.

So, get ready to learn some valuable tips and tricks that will help you take your sublimation printing game to the next level.

you may also like:

- Can You Remove Sublimation Ink from Different Blanks?

- Butcher Paper vs Parchment Paper For Sublimation

- How To Sublimate a 30 Oz Curved Tumbler (Step By Step!)

- Is Sublimation Printing Eco-Friendly?

Why Sublimation Black Looks Grey

Several factors can contribute to your sublimation black appearing gray. Understanding these reasons is crucial in addressing the issue effectively.

1. Ink Limitations

Sublimation inks work by converting from a solid to a gas during the heat press process. While black ink creates a dark color, achieving a perfect black like traditional printing methods can be challenging due to the inherent properties of these inks.

The dye particles in sublimation inks are designed to convert into a gaseous state, which can sometimes result in a less intense color saturation compared to traditional printing methods that use pigment-based inks.

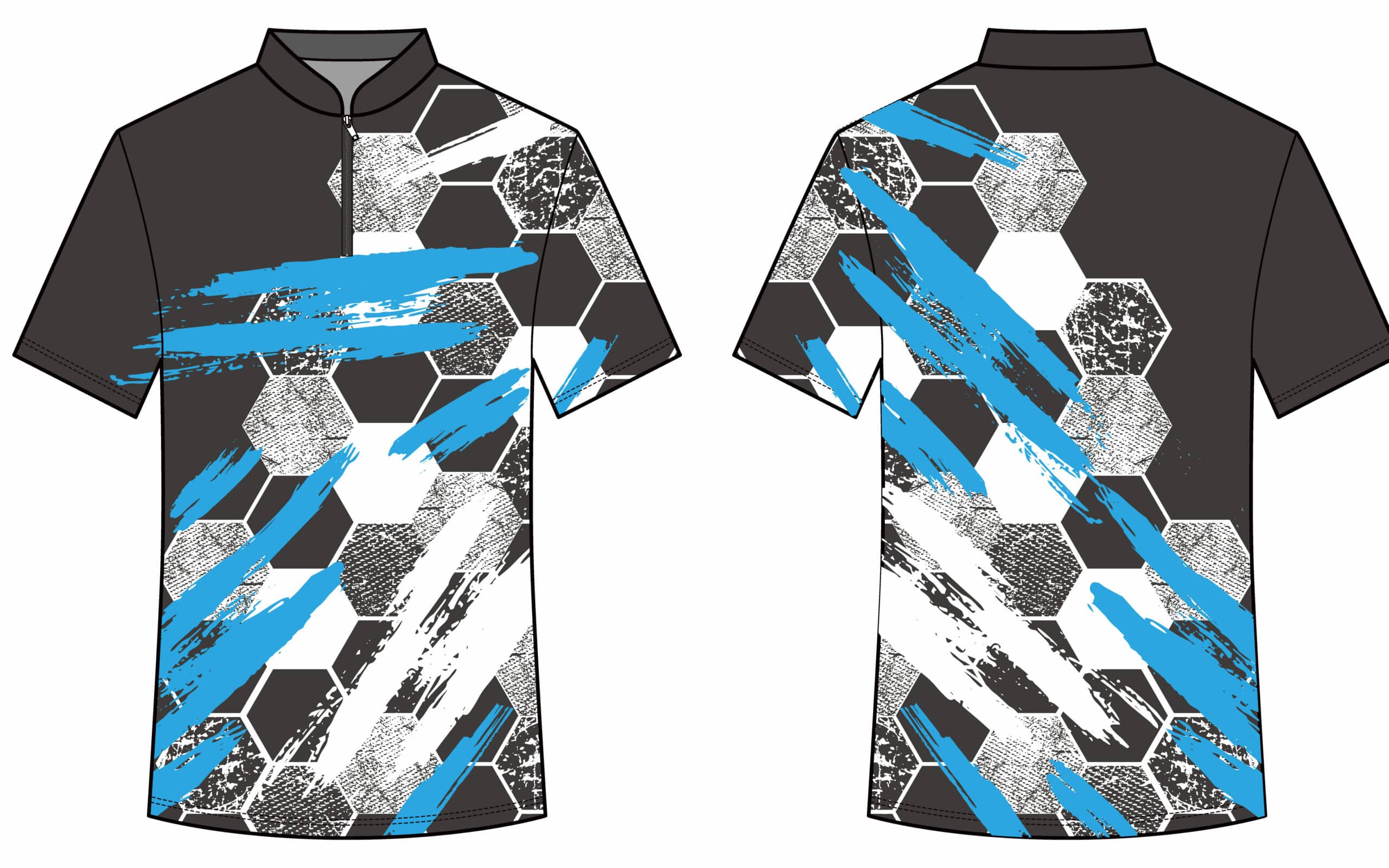

2. Fabric Limitations

The polyester fibers in the blank absorb the dye, affecting the final color output. Black can sometimes appear slightly washed out or gray on the fabric compared to how it looks on the transfer paper.

If the fabric has a lower polyester content or a more loosely woven structure, it may not be able to effectively absorb and retain the dye particles, resulting in a less intense and potentially grayish appearance of the black color.

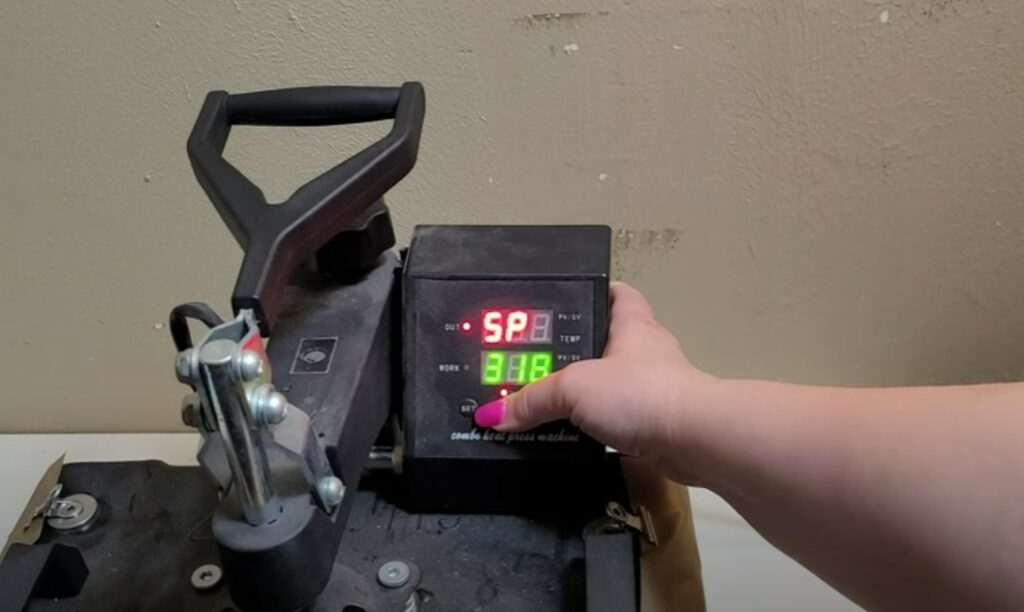

3. Incorrect Temperature Settings

Improper temperature settings during the heat press process can lead to incomplete dye sublimation, resulting in a grayish appearance instead of a rich black.

The temperature settings are crucial for ensuring that the dye particles are fully converted into a gaseous state and adequately absorbed into the substrate material.

If the temperature is too low, the dye particles may not fully sublimate, leading to an uneven or incomplete transfer of color. On the other hand, if the temperature is too high, it can potentially cause the dye particles to become unstable.

4. Insufficient Ink Coverage

If the transfer paper does not have enough black ink coverage, it can result in a faded or grayish print on the final substrate. The amount of ink coverage on the transfer paper is directly related to the intensity and vibrancy of the final print.

Insufficient ink coverage can occur due to various reasons, such as low ink levels in the printer, clogged print heads, or incorrect printer settings.

5. Low-quality ink or Paper

Using low-quality sublimation inks or transfer papers can compromise the color vibrancy, leading to a dull, grayish black.

High-quality sublimation inks are specially formulated with dye particles that are designed to effectively sublimate and bond with polyester fibers, ensuring vibrant and long-lasting colors.

Similarly, high-quality transfer papers are coated with a special polymer that facilitates the transfer of the dye particles from the paper to the substrate during the heat press process.

6. Environmental Factors

Environmental conditions, such as humidity and temperature, can also play a role in how the sublimation inks perform during the transfer process.

Similarly, extreme temperatures (either too hot or too cold) during the transfer process can affect the sublimation process and result in a grayish or dull appearance of the black color.

How to Prevent Sublimation Black from Turning Grey

Now that you understand the potential causes, let’s dive into practical solutions to help you achieve that coveted true black in your sublimation projects.

1. Use Rich Black Ink

Some sublimation ink manufacturers offer “rich black” inks specifically formulated for deeper blacks. These inks may contain a higher concentration of black dye or additional color components to achieve a richer result.

These specialized inks are designed to provide a more intense and vibrant black color, helping to overcome the limitations of standard sublimation inks.

2. Multi-Layer Printing

You can try a multi-layer approach for a more intense black. This involves printing several layers of black ink on top of each other during the heat press process.

By layering multiple passes of black ink, you can effectively increase the density and concentration of dye particles on the transfer paper, resulting in a more intense and vibrant black color once transferred to the substrate.

3. Adjust Temperature Settings

Ensure that you are using the correct temperature settings for the specific substrate you’re working with.

Each substrate material has a specific temperature range that is optimal for the sublimation process. If the temperature is too low, the dye particles may not fully sublimate, resulting in a dull or grayish appearance.

Conversely, if the temperature is too high, it can cause the dye particles to become unstable or even degrade, leading to color shifts or fading.

4. Increase Ink Coverage

In your design software, consider slightly darkening your black compared to how you want it to appear in the final product. This can account for the slight lightening that often occurs during sublimation.

By increasing the ink coverage or density of the black color in your design, you can compensate for the potential color loss or dilution that may occur during the sublimation process.

This approach can help ensure that the final print retains a deep, rich black color even after the transfer to the substrate.

5. Use High-Quality Supplies

Invest in high-quality sublimation inks and transfer papers designed specifically for this printing process. These premium supplies are engineered to handle the sublimation process effectively, resulting in better color retention and vibrancy.

High-quality sublimation inks are formulated with dye particles that are optimized for the sublimation process, ensuring consistent and vibrant color reproduction.

While high-quality supplies may come at a higher cost initially, they can save you time, effort, and materials in the long run by producing consistent and high-quality results.

6. Maintain Optimal Environmental Conditions

Ensure that your workspace is properly controlled and maintained at optimal conditions for successful sublimation printing. This includes monitoring and regulating factors such as humidity and temperature.

High humidity levels can cause the dye particles to become unstable or degrade, leading to a less intense color output.

Similarly, extreme temperatures (either too hot or too cold) during the transfer process can negatively impact the sublimation process and result in a grayish or dull appearance of the black color.

7. Perform Regular Maintenance

Regular maintenance of your sublimation printing equipment can help ensure consistent and high-quality results. This includes cleaning the print heads, unclogging nozzles, and calibrating the printer settings.

Clogged print heads or nozzles can lead to uneven ink distribution and inadequate ink coverage, resulting in a grayish or faded appearance of the black color.

Regularly cleaning and maintaining your printer can help prevent these issues and ensure optimal ink flow and color vibrancy.

Frequently Asked Questions

Below are a few frequently asked questions:

Why is my sublimation printer not printing dark enough?

There could be several reasons for this, including low ink levels, clogged print heads, or incorrect printer settings. Start by checking and refilling the ink cartridges if needed, and then perform a print head cleaning cycle.

What can I spray on sublimation to make it brighter?

While there are no specific sprays or coatings recommended for enhancing the brightness of sublimation prints, ensuring that you’re using high-quality sublimation inks, and following the correct temperature settings can help achieve vibrant and vivid colors.

Wrapping Up

Throughout this article, we’ve explored the various reasons why your sublimation blacks might appear gray, and we’ve provided you with practical solutions to help you achieve that coveted deep, rich black you’ve been longing for.

From understanding ink limitations and fabric properties to adjusting temperature settings and utilizing specialized inks, we’ve covered a wide range of techniques to tackle this common issue.

Whether you’re a seasoned sublimator or just starting out, these tips and tricks will help you elevate your skills and produce stunning black designs that truly pop.

Don’t be discouraged if you encounter setbacks or challenges along the way. Sublimation printing is an art form, and mastering it takes time and practice.