Have you ever wanted to add a customized design to a paper craft project or bake a cake with a unique birthday message?

If so, you may have wondered if you can use the sublimation printing process on regular cardstock.

I get it – sublimation can create cool effects on fabrics, mugs, and more. But cardstock is different than those materials.

So will it actually work? And what challenges might you run into if you try sublimating cardstock?

In this article, I’ll give you the complete low-down on whether sublimation and cardstock can mix.

We’ll cover what is required to sublimate cardstock, tips for success, potential issues to troubleshoot, and even some alternative options if sublimating cardstock doesn’t pan out for you.

So brew your favorite beverage, grab your glitter cardstock, and let’s solve this crafting mystery!

Can You Sublimate on Cardstock?

The short answer is yes, you can sublimate certain types of cardstock! But the ink will only transfer properly if the cardstock has a polymer coating for the gaseous ink to bond to.

Regular paper cardstock without any coating will not work. The ink just won’t adhere correctly.

Watch this amazing video by Jennifer Maker for better understanding:

What Makes Cardstock Sublimation-Ready?

For the best shot at sublimating cardstock, you need paper that has either of these qualities:

- Contains polyester – This is why sublimating standard glitter cardstock often works well. The glitter itself provides polymers that accept sublimation ink.

- Coated with a polymer-based product – Special sublimation coatings and sprays add a polymer layer so dyes bond properly.

As long as your cardstock checks one of those boxes, you’ve got a fighting chance!

Below are the most common cardstock options people have success sublimating:

- Glitter cardstock – The glitter polymers allow ink bonding. Just avoid heavy coats of glitter that obstruct ink transfer.

- Cardstock brushed with polycrylic coating – Polyacrylic sealer sprays provide the needed polymer layer.

- Cardstock laminated with polyester pouch – Pouches create a polymer barrier for dyes to interact with.

- Cardstock coated with “subli-glaze” products – Special sublimation glazes add polymer protection.

Challenges of Getting Good Cardstock Sublimation

While the cardstock styles above can be sublimated, getting perfect results still tends to be tricky:

- You need very high heat (400°F+) and substantial pressure for ink to properly sublimate onto cardstock. This can exceeded home iron capabilities.

- Cardstock corners often fade during pressing as it’s hard to evenly coat cardstock edges.

- An extremely uniform polymer coat is essential for the ink to adhere correctly across the entire design. Any thin spots lead to poor ink coverage.

Be prepared to do some trial and error dialing in your specific cardstock, coating methods, temps, times, and press pressure.

Best Practice Tips for Sublimating Cardstock

Since intricacies exist when sublimating onto cardstock, following best practice recommendations gives you the greatest chance of print quality success:

1. Use a Heat Press Over the Home Iron

For even heat and pressure distribution across cardstock, I highly suggest using an actual heat press over an iron.

Dialing in precise temps and timer settings combined with an even pressing surface gets better sublimation results on cardstock.

An iron likely won’t cut it – there’s too much room for uneven pressure areas leading to faded spots.

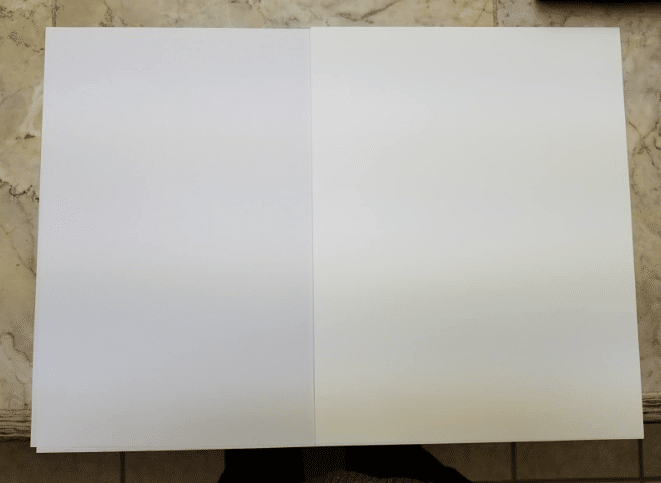

2. Select Quality Coated Cardstock

Not all glitter cardstock works the same! Test brands and types of polymer coated cardstock to compare ink vibrancy and coverage. For example, avoid cheaper glitter cardstock where the thick coat of glitter prevents ink bonding.

Higher quality pre-coated cardstock leads to better sublimation than trying to DIY coat basic cardstock at home. But experiment to find what specific products pass your quality tests.

3. Securely Tape Transfer Paper Before Pressing

Carefully tape down sublimation transfer paper before pressing to minimize any movement.

Keep paper firmly matched to cardstock edges to prevent blurring.

Slowly remove your heat press straight up after the timer finishes for clean separation between transfer paper and cardstock.

4. Press Cardstock on Permanent Surface

Press sublimation cardstock on a flat, hard surface – avoid any fabric padding. Using something like a mug press on top of a silicone mat for example won’t offer enough sturdiness.

Permanent surfaces like a smooth countertop provide support needed for cardstock.

And those are the top considerations for improving cardstock sublimation results!

Next let’s explore some alternative customization methods if you decide sublimation isn’t the best match for cardstock projects.

Alternative Cardstock Customization Options

While sublimating cardstock can yield nice products, it may remain finicky compared to substrates like polyesters.

If you try sublimating cardstock and remain unsatisfied with print durability, ink vibrancy, or get tired of dealing with precise temps – consider switching to these alternative DIY customization techniques instead:

- Vinyl – Apply adhesive vinyl with a Cricut or other cutting machine. This allows vibrant color effects without ink.

- Engraving – Use an engraving tool to carve personalized designs directly into cardstock.

- Screen printing – Works better than sublimation for covering larger cardstock areas with color.

- Sublimation on polyester – Shift to sublimating easier-to-use polymer fabrics, banners, etc. instead of fussy cardstock!

All of those options bypass common cardstock sublimation headaches. The right call is embracing a more reliable approach that saves frustration and gets products you love!

Now let’s examine some possible troubleshooting issues when working with sublimated cardstock.

Tips For Cardstock Sublimation

Pressing beautiful cardstock sublimation designs does come with a learning curve. But adjusting a few key factors helps immensely if you run into trouble:

1. Test Multiple Brands of Cardstock

Experiment with different brands and types of cardstock until colors pop vividly. As we discussed earlier, cheaper options likely won’t cut it.

Be ready to try 3+ kinds to judge dye intensity, image sharpness, durability, and texture preservation through pressing heat.

And remember – quality glitter cardstock often performs lightyears better than basic cardstock with DIY polymer spray.

2. Verify Complete Ink Coverage

Make sure to tape down sublimation transfer paper extremely securely before pressing onto cardstock. Any slight paper movement mid-press blurs design edges.

After the timer finishes, slowly peel back the heat press straight away from the cardstock. Avoid pulling paper around on the surface or hastily ripping it off which can shift ink placement.

3. Allow Proper Cool Down Before Handling

I know it’s tempting to immediately hold that warm, freshly pressed cardstock piece to admire it… but wait! Let sublimated cardstock completely cool to room temp before touching to prevent accidentally smudging ink.

Give it a few minutes rest on the pressing surface to properly set.

4. Work in Well-Ventilated Area

The sublimation process releases noticeable fumes as ink transitions from solid to gas. Make sure to turn on a fan or open some windows in your work area so ventilation whisks away strong odors. Don’t press cardstock in closed spaces!

And perhaps go easy on simultaneously sniffing permanent markers as I occasionally do…

5. Adjust Cricut Machine Pressure

Using a Cricut machine to cut cardstock after pressing? The high heat and pressure of sublimation can alter cardstock texture, requiring adjusted Cricut pressure so blades fully cut through.

Plan on doing test cuts with scraps to determine ideal blade force. And you may need multiple passes for clean cuts on detailed shapes.

Pro Tip: Save cut setting tweaks in Design Space for future recall when cutting sublimated cardstock pieces!

Time to Get Pressing!

Now you’re armed with complete expertise on successfully sublimating cardstock thanks to this exhaustive guide!

We covered critical factors like:

- Polymer coating requirements for proper ink bonding

- Recommended cardstock types and application methods

- Useful equipment like quality heat presses

- Key printing and pressing best practices

- Troubleshooting adjustment tips

- Alternative customization options if sublimation doesn’t work for your projects

Hopefully you feel totally prepped to give sublimating your favorite cardstock a test drive!

While some challenges exist working with cardstock and sublimation ink, following the advice above sets you up for the best results.

The joy of customizing paper crafts, unique cake toppers, and other cardstock ideas makes tinkering with sublimation worth it.

And getting imagines to successfully transfer in vibrant color is so rewarding!

Now get out there, practice those cardstock