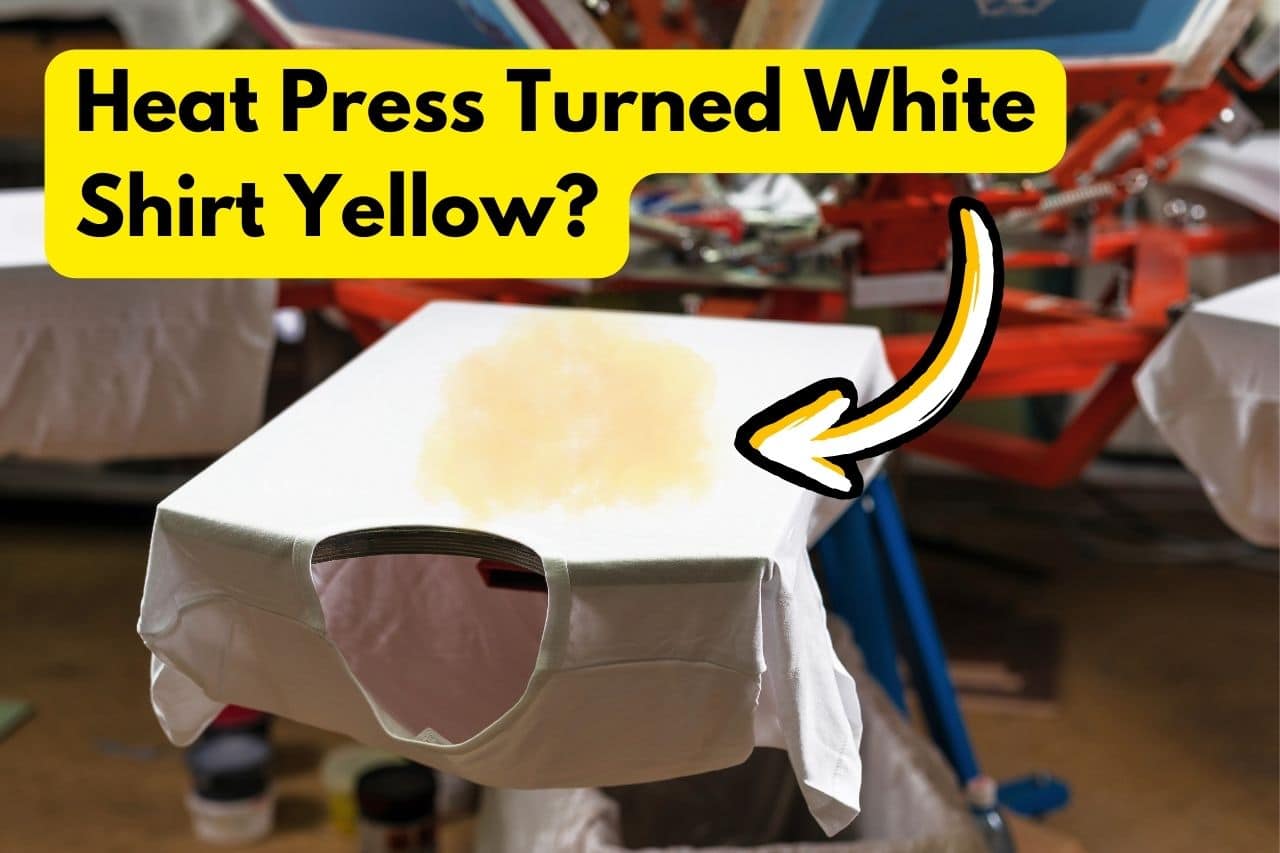

You excitedly prepared your brilliant t-shirt design and carefully centered the shirt on your trusty heat press.

After pressing with your standard settings, you slowly peel back the paper to reveal…a yellow splotch on that crisp white shirt!

We’ve all seen that dreaded yellowing and staining from too much heat exposure. It instantly ruins the clean look you worked hard to achieve.

If you’ve faced this heartbreaking issue of a heat press turning white shirts yellow, this guide covers everything about the root causes, solutions, preventions, and remedies to try.

What Factors Cause White Shirts to Turn Yellow in a Heat Press?

Before exploring fixes, let’s break down the key culprits behind white fabric yellowing during heat pressing:

1. Excessive Time and Temperature Settings

The number one offender is simply exposing the white fabric to too high of temperatures for too long while pressing. Most white t-shirt fabric can only withstand mid-range heat of 375°F or below before yellowing happens.

Pass that threshold even slightly and discoloration occurs.

2. Heavy Pressure Amounts

Along with overly hot temps, applying too much concentrated downward pressure crushes shirt fibers more intensely.

Pressure intensifies heat damage. Some materials need only light pressure.

3. Trapped Moisture in Shirts

If white fabric retains any dampness from washing or storage, pressing heats that lingering moisture into steam.

Pressing heat reacts with shirt moisture to create a yellow chemical reaction. Dye scorching also occurs.

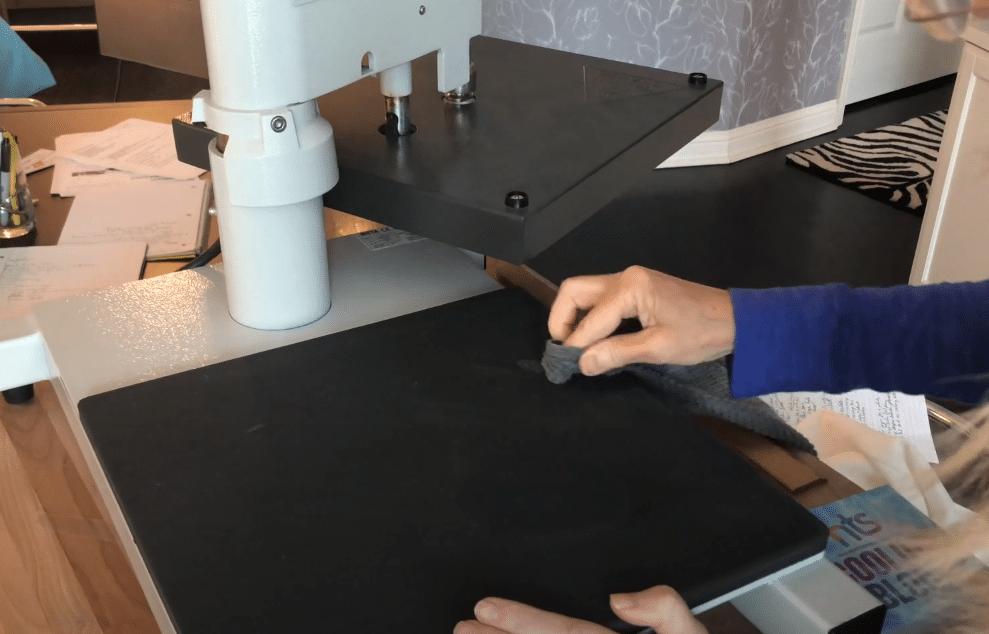

4. Dirty Heat Platen Surface

Lint, debris, and shirt fibers stuck on your heat-press surface often transfer yellow stains back onto the next projects. Tacky platens pick up and redeposit discoloring gunk.

And those are the 4 biggest factors that create yellow-tinted heat press nightmares!

check this amazing video on how to clean a heat press by Heat Transfer Source: Dependable Vinyl Solutions

Easy Fixes to Stop Your Heat Press Ruining White Shirts

Luckily several adjustments make preventing white shirts from turning yellow quite straightforward:

1. Lower Temperature and Time Settings

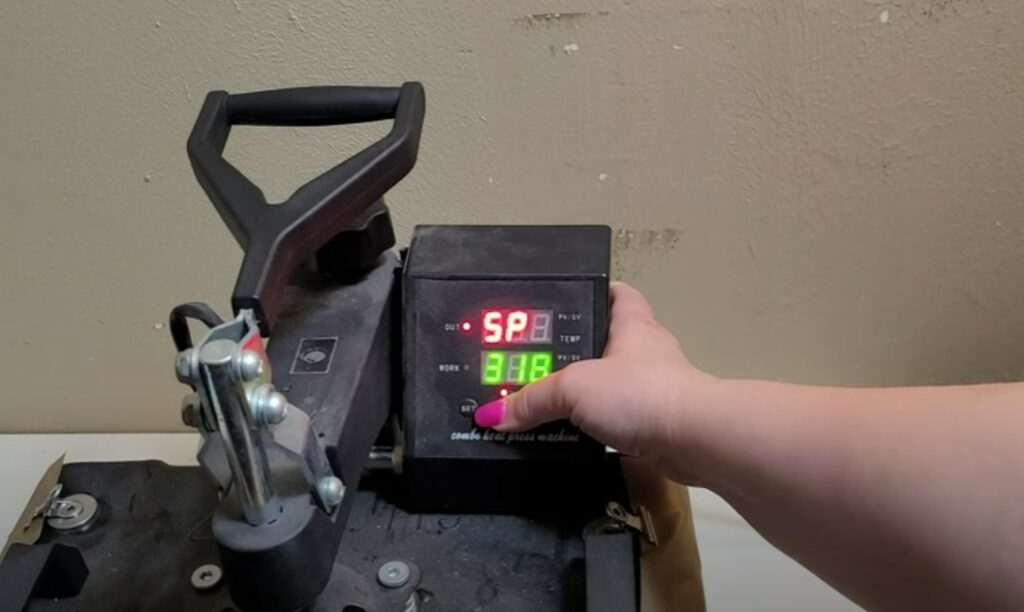

The simplest solution is dialing back your heat press temp closer to 375°F or below when pressing lighter fabrics. Never exceed 400°F on white shirts!

Shorten your time duration to 25 seconds or under too. Extending heat exposure intensifies damage even if the temp is in a safe zone. Find the shortest time to properly cure inks at cooler temps.

2. Apply Appropriate Pressure

Use light to medium pressure with lighter fabrics like white cotton shirts – avoid maxing out pressure. Start on the lowest setting and slowly increase only if ink adhesion seems weak after initial tests.

3. Insert Protective Barrier Sheet

Placing a sheet of parchment paper or Teflon sheet during pressing prevents direct heat contact scorching fabrics.

The protective barrier absorbs much ambient heat before it hits shirts.

4. Allow Cool Down Before Removing Paper

It’s tempting to immediately hold up that hot shirt after the press beeps…but don’t! Letting shirts cool to room temp before grabbing stabilization inks and prevents smudging or distortion.

And remember – test all new materials with fabric swatches before pressing final live products!

Pro Tip: Program common heat press setting presets for certain fabric types like white shirts into digital heat press machines for fast recall!

Still Seeing Yellow Shirts? Try These Extra Tips

If you follow the previous advice but still sometimes get yellowed white shirts, a few secondary factors may be the cause:

– Buy Higher Quality Shirts

Cheaper white shirt blanks use flimsier materials and less concentrated white fabric dyes. Higher grades of beefy cotton tees can better handle heat exposure without degrading or scorching as quickly.

– Check Moisture Levels Before Pressing

Store blank shirts properly to prevent moisture retention, and avoid over-washing shirt blanks. Pressing wetness evaporates into steam, carrying yellow dyes during heat reactions. Completely dry shirt blanks first for immaculate pressing.

– Clean Your Heat Platen Frequently

Use isopropyl alcohol to thoroughly wipe down your heat press platen every 10 prints or so. This prevents residue buildup from transferring stains back to shirts. Tacky gunk indirectly causes yellowing. Keep surfaces pristinely clean.

With those extra tweaks, your white shirts press beautifully time after time without any hint of yellow discoloration!

What If Yellow Stains Already Happened on a White Shirt?

Ah shoot, your white shirt already came out with yellow blotching after heat pressing. Is there anything to be done for damage control at this point?

While you may need to scrap the shirt if stains are heavy, try these remedies to remove mild yellow spots and rescue mildly affected shirts:

Hydrogen Peroxide & Dish Liquid Mixture

- Mix equal parts hydrogen peroxide and any dish liquid in a glass

- Pour it over any stained areas of the shirt

- Place a sheet of parchment paper atop a sprayed section

- Press for 10-15 seconds to draw out discoloration

- Check results – respray if needed

The chemical reaction this mixture creates helps erase many fabric yellow stains!

Purchase a Commercial Scorch Removal Spray

Specialized scorch and burn removal products are stronger than homemade solutions. The powerful enzymatic formulas break down stubborn yellow dye oxidization.

However – test first in a small hidden area to ensure the spray ink doesn’t react with fabric print inks!

While attempting to remove severe yellow stains risks further damaging shirts or prints, mild cases often respond very well to corrective products.

And at minimum, reshooting mild yellow shirt sections lets you cover up mistakes with an additional print layer!

When All Else Fails…Outsource Printing!

If no combination of equipment, technique, or remedy fixes heat press yellowing on white shirts from your production, consider outsourcing printing.

Screen printing shops with commercial convection dryers don’t expose fabrics directly to scorching heat or pressure. They also have finer tuned procedure experience.

Outsourcing helps minimize damaging shirts for very large print orders. The rates become cost-effective at high quantities too.

So don’t bang your head against the wall struggling with yellow shirt headaches – hand off projects to the experts when needed!

Let’s Review the Key Causes and Solutions

We covered an epic amount of critical troubleshooting for reversing heartbreaking white shirt yellow stains from heat pressing mistakes:

- The main factors: excess temperature, extended press times, heavy pressure, trapped shirt moisture, dirty platen residue

- Easy solutions: correct time and temp settings, apply ideal pressure levels, use barrier sheets, keep platens clean

- Advanced fixes: purchase higher grade shirt blanks, address moisture retention issues, frequently wipe platens

- Stain removal methods: hydrogen peroxide mixtures, commercial removal sprays

- When to outsource: once solutions fail on large orders

With so many handling steps during pre-press shirt preparation, pressing, and post-press finishing – mistakes sneak in. But now you can catch those errors early and know how to combat yellowing!

Time to Keep White Shirts White!

I hope this exhaustive deep-dive into the intricacies of heat press turned white shirts yellow gives you immense clarity and confidence. Understanding the science behind what factors enable discoloration makes prevention second nature rather than frustrating guesswork!

You must remember:

- Cotton and polyester shirts yellow at too high temps

- Moisture exposure and dirty platens cause issues

- Barrier sheets protect shirts from scorching

- Test ALL materials before live production pressing!

The satisfaction of peeling back pristine snow-white shirts from the heat press is a magical moment after putting so much preparation into design work. Don’t allow preventable heat and pressure mishaps to take that feeling away!

Now get out there, dial in those fabric-appropriate settings, keep plenty of hydrogen peroxide supply handy just in case, and show off those vibrant prints on bright white backgrounds! No more yellow tints ruining perfect apparel.