Have you ever wondered how many prints you can get from a single sublimation ink cartridge?

It’s a question that many people who work with sublimation printing ask themselves, and the answer can be quite complex.

The number of prints you can produce from a single cartridge isn’t a one-size-fits-all figure because numerous factors can influence the yield.

In this comprehensive article, we’ll delve into ‘How many prints per sublimation cartridge can you get?’ along with the factors that affect the print per ink cartridge.

We’ll also provide you with practical tips, strategies, and industry knowledge to help you navigate the intricate world of sublimation printing and ink cartridge usage efficiently.

So, let’s get started!

you may also like:

- How To Sublimate a 30 Oz Curved Tumbler (Step By Step!)

- Can You Sublimate On Coir Doormat? (Yes You Can, But…)

- How Do I Make My Sublimation Brighter? Pro Tips

- Can Sublimation Ink Go Bad? (Reasons & Preventions)

How Many Prints Per Sublimation Cartridge Can You Get?

It’s hard to say exactly how many prints you can get from one sublimation ink cartridge. It depends on a lot of things, like how big the prints are and how much ink they use.

On average, most people can print around 200 prints from one sublimation cartridge. But that number can be higher or lower.

Some cartridges might print as few as 50 prints. Other cartridges could print up to 500 prints if the prints are small and don’t use much ink.

The quality of the cartridge and printer matters too. Good quality equipment uses ink slowly so the cartridge lasts longer. Bad quality equipment wastes more ink so you get fewer prints.

The size and details of the design you’re printing also make a difference. Large, colorful designs use more ink per print. Simple designs with less color use less ink per print.

Factors Affecting Print Per Ink Cartridge

Many variables impact the number of prints per cartridge:

1. Cartridge Size

Cartridge size directly correlates to the ink volume held inside. Standard consumer cartridges hold around 100ml of ink. Bulk professional versions go up to 250ml+ capacities.

Larger cartridges equal more prints. A basic 100ml cart might yield 100-150 prints whereas a 250ml version could provide 300+.

When purchasing cartridges, seek bulk discounts on high-volume packs. The price per ml drops substantially when buying cartridges in bulk

2. Image Coverage and Design Factors

Image dimensions and ink coverage density greatly affect ink usage. Photographic images inherently use more ink than basic logos or text prints. Solid colors consume ink faster than white or blank space on a product.

For example, an 8”x10” photo print likely uses 5-10ml of ink depending on the printer density settings. Meanwhile, a simple 3-color company logo printed on a pocket tee shirt may only use 0.5-1ml of ink.

3. Printer Settings and Modes

The printer resolution, print mode, ink saturation, and other settings affect print yields per cartridge. Higher resolutions produce extremely professional quality outputs but use significantly more ink per print.

For example, 1440 dpi resolution consumes noticeably more ink compared to 720 dpi prints. This makes lower resolutions preferable for draft-mode printing.

Printer settings also control the ink vibrance and density. Higher density settings lead to more vibrant colors but cause faster cartridge depletion per print.

When doing test prints, start at low ink densities and gradually increase to find the ideal vibrance without wasting excess ink.

4. Substrate Materials and Pre-treatments

Ink absorption and usage varies widely across different materials like fabrics versus hard goods. Ceramics, metals, and glass require heavy full ink coverage to produce brightly colored images since they absorb less ink inherently.

To counter this, products like chroma-blast sprays can coat surfaces to significantly increase ink absorption and yield much better print quality on non-fabric items.

Fabrics themselves have major variations in how much ink they uptake depending on material blends and compositions.

Fabric pre-treatments make many fabrics exponentially more receptive to sublimation inks but also lead to much faster absorption.

Strategies for maximizing prints per sublimation cartridge

While yields will always vary, utilize the following tips for ink efficiency:

1. Printer Maintenance

Performing regular maintenance keeps print heads clear of debris allowing for better ink flow and less clogging issues over months of printing.

Clogs from dust, lint, and particles can completely block ink resulting in patchy prints. Cleaning every few hundred prints prevents reduced quality.

Replacing cartridges as advised per the manufacturer guidelines also prevents trying to push past empty with damaged print heads. Running completely dry permanently destroys the quality of printer print heads.

2. Choosing the Right Paper and Fabrics

Choosing papers and fabrics with absorption rates matched to the sublimation ink type results in substantially less wasted ink from over-saturation.

High-absorption papers leave less excess ink residues for reuse but deliver finished prints faster versus slower absorbing substrates. This makes lower-absorption papers last longer per page.

When possible, purchase sublimation papers and fabrics specifically engineered to work with the ink for ensured quality results from known compatible materials.

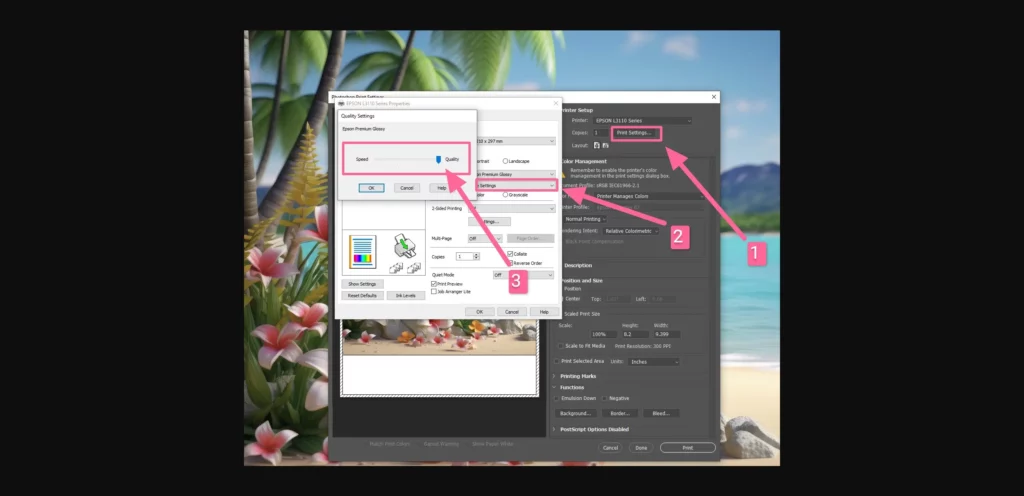

3. Adjusting Printer Settings

Understanding the full range of adjustments and modes for a given printer is key to maximizing ink efficiency.

Printer settings impact vibrance, absorption, and precision application on the media. initial test prints should use draft modes which limit ink flow while finding the ideal print size and alignment.

With positioning set, low ink densities lock in precise coverage and then increase gradually to lock in vibrance without over-saturating. If densities get set too high initially it wastes ink flooding past the point of usable absorption in the material.

4. Tracking Usage Statistics

Analyzing average ink usage over past prints provides insights by recording the total prints per cartridge on the various papers and fabrics printed.

As bulk ink pricing fluctuates seasonally, updating running cost estimates annually maintains real budgeting. Dial in profitability with ever-evolving expenses.

These usage rates carry over directly into accurate per-print job quoting based on average cartridge yields.

Should outlier orders consume way above average, the job becomes a case study for design improvements to reduce waste on repeats. Tighten efficiencies over time while still keeping clients delighted on every job big and small.

Watch the below video to get information about sublimation inks for Epson Ecotank printer:

Frequently asked questions

Frequently asked questions to deepen your understanding:

How long does sublimation ink last in the printer?

Ink lasts 6-12 months in the printer at most when properly maintained. Longer durations risk drying out and permanent clogging from lack of use cycling ink through print heads.

Refrigerating spare unopened ink cartridges halts the chemical changes of inactive sublimation ink to last 1-2 years in cold storage.

How much surface area can 1 ml of ink cover?

General estimates range from 1-3 square feet of coverage depending on the density settings chosen and the efficiency of the printer model putting down the ink.

So theoretically, a standard 100ml cartridge potentially prints between 100-300 square feet of images or designs.

How many 8.5” x 11” prints from a full cartridge?

For a 100ml cartridge, one may yield 100-250 letter-sized prints depending heavily on the density and dimensions of image coverage across the print material.

However, overall ink efficiency varies widely across models and manufacturers. Refer to niche forums discussing real-world yields for your specific printers from fellow users’ experiences.

Wrapping Up

In summary, the number of points you can get from a sublimation ink cartridge can vary greatly depending on several factors, including the cartridge size, image coverage and design, printer settings, and the substrate materials being printed on.

While some cartridges may produce as few as 50 prints, others could yield up to 500 prints or more, especially if the prints are small and don’t use much ink.

Proper maintenance of your printer, choosing the right papers and fabrics, adjusting printer settings, and tracking usage statistics can help you maximize the number of prints you can get from each cartridge.

If you found this article helpful or have any additional tips or experiences to share, please leave a comment below!