Sublimation printing is such a game-changer when it comes to decorating fabrics and apparel.

It lets you permanently print full-color graphics, photos, and designs directly into fabric made of polyester or certain polymer-coated materials.

The prints fuse right into the fabric at a molecular level rather than sitting on top. The results are bright, vibrant, resilient prints that hold up amazingly well to washing and wear.

No cracking, peeling or fading like you see with screen printing.

Now when it comes to hats, acrylic knits are one of the most common materials used, especially for winter beanies and caps.

But can you use the sublimation process on these acrylic hats?

The answer is a resounding yes!

In this guide, we’re going to explore sublimating on acrylic hats from start to finish. I’ll share tips on:

- How sublimation works so well with acrylic

- Pre-treating acrylic hats before pressing

- Step-by-step sublimation process

- Recommended times, temps, and pressure

- Troubleshooting mistakes

- Getting perfect results every time

Let’s start by looking at why acrylic and sublimation go so well together…

Why Acrylics Work So Well for Sublimation Printing

The reason sublimation technology pairs perfectly with acrylic knit hats is thanks to the polymeric composition of acrylic fabric.

You see, acrylic fibers are made from polyacrylonitrile, a synthetic polymer material. It’s essentially plastic in thread form!

On a molecular level, these polymers bond very readily with the sublimation dyes when heat and pressure are applied during the sublimation process.

It’s not just a surface-level print sitting on top of the acrylic. The sublimation inks infuse into the actual fibers themselves. This makes the prints extremely durable compared to other decorating techniques.

Let’s look more closely at why acrylics are so ideal for sublimation:

1. Acrylic Fibers are Made of Polymer

- Acrylic fabric contains at least 85% polyacrylonitrile polymer, usually more.

- The remaining 15% is vinyl acetate or methyl acrylate, also polymers.

- This high polymer content allows the fibers to readily accept sublimation dyes.

- The dyes form a permanent bond at a molecular level within the acrylic itself.

2. No Additional Polymer Coating Needed

Here’s an interesting fact about acrylic and sublimation:

For most textiles like cotton, you need to apply a polymer coating first to prepare the material for sublimation.

But with acrylic, no additional polymer coating is required since the fibers themselves already contain such high polymer content.

This saves you a step in the preparation process!

3. Vibrant, Durable Print Results

Because the inks infuse into the fibers rather than sitting on the exterior, sublimation on acrylics produces incredibly vibrant prints that hold up very well:

- Deep, saturated colors that won’t fade over time

- Photographic printing with precision detail

- Soft hand feel – doesn’t leave a heavy layer on the fabric

Now you understand the science behind why sublimation technology pairs so perfectly with acrylic hat materials.

Next, let’s look at how to prep and sublimate acrylic beanies step-by-step…

Step-by-Step: Sublimating on Acrylic Hats

To properly sublimate acrylic hats, there are some key steps to follow:

1. Design and Print Your Image

First things first – create your image design however you wish. Use Photoshop, Canva, Illustrator, or whatever works for you.

Print a mirrored image onto sublimation paper using a suitable color printer and sublimation inks.

Pro Designer Tip: Print a couple extra copies just in case!

2. Check the Hat Composition

Before pressing, check the label to verify the exterior shell of the hat is acrylic. Sometimes the inner lining may be cotton or polyester.

As long as the outer material is acrylic, you’re good to go.

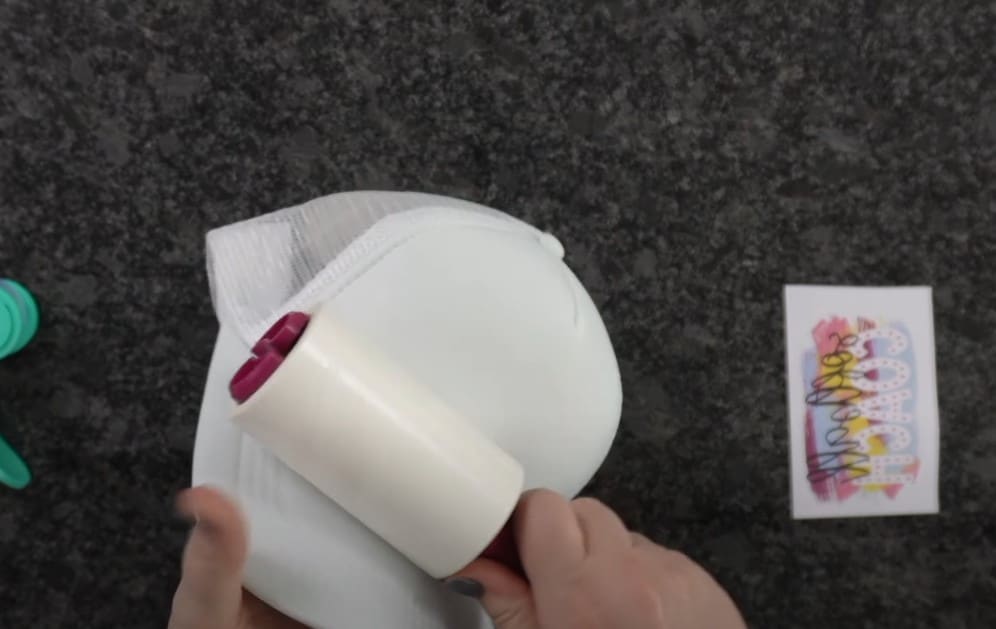

3. Clean and Press the Hat

To prep the hat:

- Clean the hat and remove the lints using a lint roller just like you do with t shirts.

- Pre-press the hat for 10-15 seconds at 375°F. This preshrinks the material slightly and removes any residual moisture.

4. Attach the Transfer Printout

- Position the transfer paper print-side down and use heat tape to attach it smoothly to the hat surface.

- Cover with butcher paper to protect the press.

5. Sublimate with Heat Press

- Press at 350°F for 45-60 seconds using medium pressure around 30-40 PSI.

- Allow to cool fully before slowly removing the paper starting at one corner.

And that’s the basic sublimation process from start to finish!

Her’s the final results:

Let’s look at some pro tips and troubleshooting next…

Pro Tips for Sublimating Acrylic Hats

Here are some handy tips and tricks I’ve learned for nailing sublimation on acrylic beanies every time:

1. Use High Acrylic Content

Not all acrylics are equal! Look for hats labeled 100% acrylic or with 85%+ polyacrylonitrile content. This creates the best bonding results.

Some budget hats may use “acrylic blends” with lower acrylic content. Avoid these – they won’t yield great sublimation results.

2. Mirror Your Image

Double check the design is mirrored horizontally before printing for sublimation. This ensures it will face the proper direction once transferred.

3. Print Extras

Sublimation paper and ink are pretty affordable. Print a couple extra transfer copies to allow for mistakes or test prints.

4. Stretch Over Press Platen

For even pressure, gently stretch the hat over the lower platen of your heat press. This flattens the material and prevents uneven printing.

If you have a specialty hat press, even better! But a standard heat press works fine too.

5. Protect Hat Seams

Watch out for seams – the extra layers of fabric cause more heat buildup which can scorch the hat if you press directly on a seam. Avoid lining up your print over top of seams.

6. Verify Time and Temperature

Use a thermometer gun to verify your press reaches the full 375°F temperature needed for sublimation. And press for at least 45-60 seconds to get a good dye transfer.

7. Let It Cool!

After pressing, let the acrylic hat cool fully before peeling the paper slowly from one corner. Peeling too soon can lead to ghosting. Patience pays off!

Follow these tips and you’ll get awesome prints every time. Next let’s go over troubleshooting…

Troubleshooting Problems with Acrylic Hat Sublimation

Here are some common problems that can occur when sublimating acrylic hats and how to fix them:

Problem: Transfer paper sticks strongly to the acrylic hat and won’t release.

Solution: Mist with water or soak the hat fully in water to help release the paper after cooling completely. Peel slowly.

Problem: Image looks faded with poor color vibrancy.

Solution: Increase time, temperature, or pressure during the sublimation press to drive more dye into the acrylic fibers.

Problem: Colors look washed out and lack definition.

Solution: The hat didn’t get hot enough during pressing. Try increasing the temperature to 380-390°F and/or pressing for a longer duration.

Problem: A ghost image is left behind after removing paper.

Solution: Don’t remove the transfer paper until the hat has cooled fully. Residual heat causes additional dye release.

Problem: Parts of the design didn’t transfer cleanly.

Solution: Ensure even pressure across the entire hat using a silicone pad or foam insert inside the hat. Stretching over the lower platen also helps.

With a bit of troubleshooting, you can achieve fantastic results sublimating acrylic winter headwear. Don’t be afraid to experiment and make adjustments until you dial in the ideal time, temperature, and pressure settings.

Sublimation vs Screen Printing for Hats

Screen printing has been the go-to method for hats for years. How does it compare to sublimation technology?

| Category | Sublimation | Screen Printing |

|---|---|---|

| Process | Dyes infuse into the fabric | Ink sits on fabric surface |

| Feel | Maintains soft hand of fabric | Can feel heavy and stiff |

| Color Vibrancy | Extremely vibrant | Moderate vibrancy |

| Print Quality | Photographic detail | Limited fine detail |

| Setup Work | Minimal setup time | Significant setup per design |

| Short Run Cost | Very affordable | High setup costs per design |

| Durability | Extremely fade resistant | Gradual fading over time |

For most applications, sublimation provides better print quality and durability on acrylic hats than screen printing.

The one advantage of screen printing is it can lay down a thicker ink layer for an opaque look.

But for photographic quality and permanence, sublimation is hard to beat! The hands-off automated process is also more efficient than labor-intensive screen printing.

Next let’s get into more sublimation tips and tricks…

FAQs About Sublimating on Acrylic Hats

Let’s go over answers to some frequently asked questions about sublimating on acrylic beanies and caps:

What’s the ideal temperature for sublimating acrylic hats?

375°F is optimal, but anything from 365°F to 385°F can work. The key is consistent heat across the entire hat surface area. Always check your press temperature with a thermometer gun first.

How do you get good pressure on acrylic hats?

Stretching the hat gently over the lower platen helps provide even pressure. You can also insert a foam block, pad or ball inside the cap while pressing for uniform pressure.

Can you sublimate acrylic blended with cotton?

Unfortunately, no. Sublimation only works on synthetic polymer fibers like acrylic or polyester. Any cotton portions of the hat won’t accept the dye. Stick with hats that are 100% acrylic.

How do you sublimate a curved cap?

Stretching the cap over the lower platen helps flatten it out. You can also use a specialty curved heat press designed for caps and hats to apply even pressure across the curved shape.

Is sublimation better than screen printing on hats?

Sublimation generally produces better print vibrancy and longevity than screen printing on acrylic hats. It also maintains the soft hand feel better. Sublimation does lack opacity, however.

Can you sublimate on knit acrylic hats?

Yes, sublimation works very well on solid knit acrylic fabrics like winter beanies thanks to the high polymer content bonding with the dyes. Stretch knits over the press for best results.

So in summary, here’s what you need to remember about sublimating acrylic hats…

Summing Up

Follow these core principles when decorating acrylic hats with sublimation:

- Verify the hat exterior is acrylic – it bonds best with sublimation dyes

- Pre-wash and pre-press the hat prior to sublimating

- Print a mirrored image onto sublimation transfer paper

- Attach transfer print-side down and cover with butcher paper

- Press at 375°F for 45-60 secs with 30-40 PSI pressure

- Allow hat to fully cool before slowly removing paper

- Stretching over platen provides even pressure

- Troubleshoot by adjusting time, temp, and pressure

It does take some trial and error to master sublimating on acrylic hats. But once you dial in the right parameters for a given hat material, you can produce stunning permanent results time after time!

The ability to customize acrylic beanies and caps with vibrant photographic prints and designs is an amazing capability made possible by sub technology.

So in summary – yes, you absolutely can sublimate acrylic hats! Follow the guidance above and you’ll be decorating awesome customizable headwear in no time.