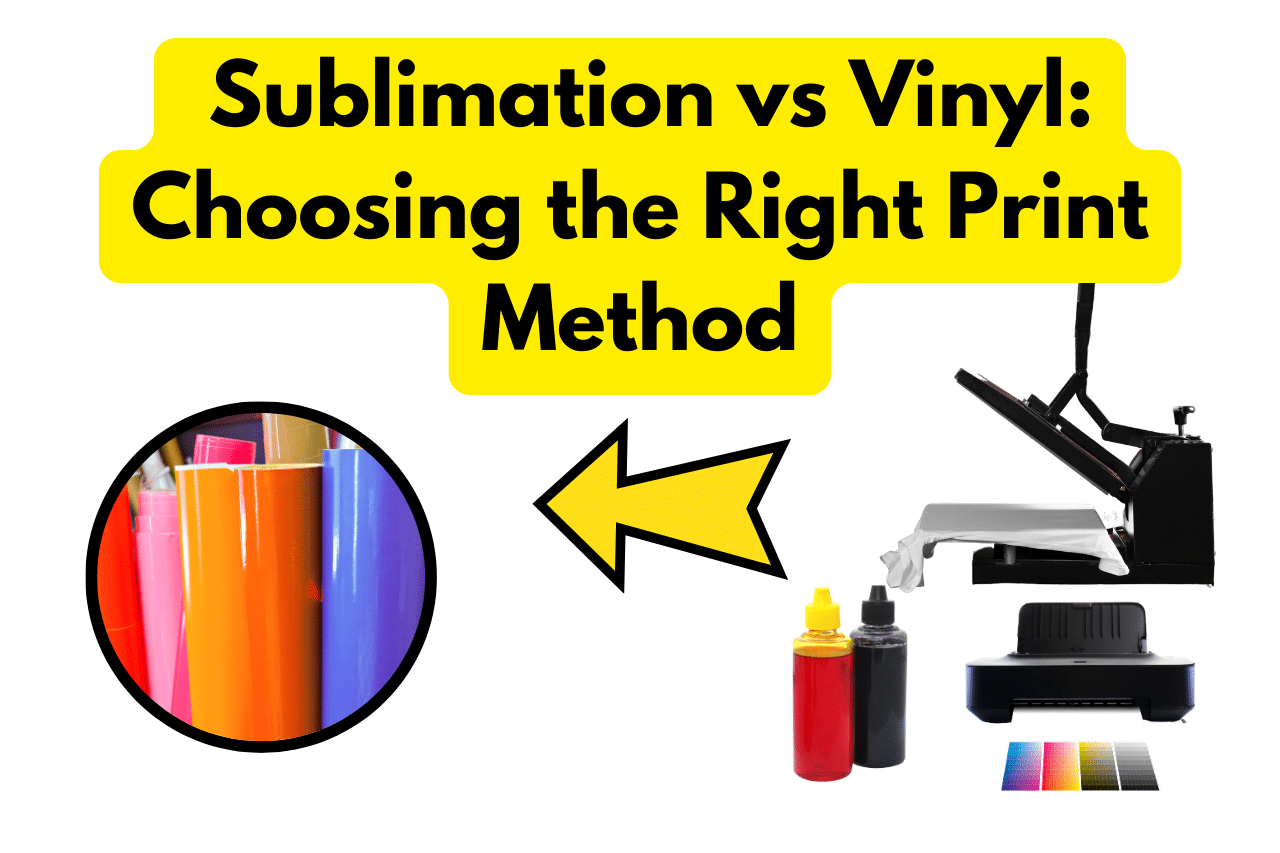

Deciding between sublimation and vinyl printing can be tricky.

Both techniques allow you to customize fabrics, hard goods, and more with vibrant designs. But they each have their own pros and cons.

In this guide, we’ll break down the key differences between sublimation and vinyl to help you determine which is the better choice for your next project.

You May Also Like:

What is Heat Transfer Vinyl?

Heat transfer vinyl (HTV) is a specialty material that can be cut into designs and applied to fabrics or other materials using heat.

It comes on rolls or sheets and is used to customize all kinds of products including t-shirts, tote bags, phone cases, ceramic mugs, wood signs, car decals

HTV contains an adhesive layer that is activated by heat. A cutting machine like the Cricut or Silhouette is used to precisely cut out a design.

Then a heat press or home iron is used to transfer the vinyl onto the material through a combination of heat and pressure.

Pros

Cons

What is Sublimation Printing?

Sublimation is a digital printing technique that uses heat to infuse printer ink into polymeric surfaces including fabrics, ceramics, and metals.

A design is printed onto special transfer paper using a professional sublimation printer and then heat-pressed onto the material.

Under high temperatures, the ink turns into a gas which permeates the substrate and then solidifies into the fibers as it cools.

The result is a fully integrated design that won’t crack, peel, or fade over time like HTV vinyl. It also allows for exceptional photorealism and gradients not possible with cut materials.

Pros

Cons

Sublimation vs Vinyl: Key Differences

Now that you know the basics, let’s explore some of the fundamental ways these two techniques differ.

1. Design Complexity

When it comes to the complexity of designs each method can produce, sublimation is the clear winner.

Because HTV relies on cutting each element precisely, it reaches limitations with photographic images, gradients, distressed effects, and high detail. Anything requiring heavy layering can also be painstaking to produce.

Sublimation, on the other hand, faces no such restrictions. It can flawlessly reproduce even the most complex full-color artwork with zero quality loss. This makes it ideal for dynamic designs with fades, bleeds, shadows, and more.

2. Product Versatility

Vinyl offers more flexibility in terms of products it can be applied to. The adhesive backing adheres to all kinds of materials from t-shirts to phone cases, ceramics, koozies, and more regardless of base color.

Sublimation does require a polymer coating to work properly so choices are narrowed down to treated polyester fabrics, hard goods like mugs, specially prepared aluminum sheets, etc.

For blank everyday cotton tees, HTV is your only option.

3. Cost Considerations

For small-scale use by crafters and hobbyists, HTV is more budget-friendly to start.

The materials are affordable and basic supplies like a Cricut machine and heat press can produce professional results without breaking the bank.

However, for photographers, graphic artists, and apparel companies producing a high volume of prints, a sublimation workflow is a smart investment.

Though initial printer and ink costs are steep, the ability to quickly generate batches of customized goods has tremendous money-making potential.

4. Ideal Substrates

HTV can be applied to 100% cotton, polyester, blended fabrics, leather, plastic, wood, glass, and metals. It also permits printing on darks.

Sublimation requires a polyester coating or at least 65% polyester content. Common substrates are high-performance wear, hard substrates like mugs and mousepads, aluminum sheets, etc.

For dark shirts, additional preparation is needed.

5. Print Quality

When imaged properly and cared for, both methods produce vibrant, eye-catching results. However, sublimation has a clear edge when it comes to color accuracy, detail, and longevity.

Because designs get embedded into the fibers rather than sitting on the surface, they retain their integrity better after repeated washing and wear.

This makes sublimation the winner for archival quality printing.

6. Durability Differences

As a permanent print process, sublimation outpaces vinyl in terms of lifespan assuming care guidelines are followed.

Instead of relying on an adhesive layer, designs get fused right into the makeup of the material itself.

HTV lasts surprisingly well through normal laundering and use but has higher risks of cracking, peeling, or lifting over time as the vinyl breaks down.

7. Eco-Impact

Both vinyl and sublimation printing allow for tremendous creativity with some environmental tradeoffs.

HTV requires less energy and equipment overall though sheets produce waste needing disposal. Many newer vinyl options are phthalate-free but some still contain PVC.

Sublimation offers a more closed-loop ecosystem with reusable printer trays and sustainable inks but leaves a larger power and hardware footprint. When disposed of properly, blank transfer sheets pose little hazard.

8. Process Comparison

Applying designs also differs quite a bit between technologies requiring distinct workflows.

HTV Application

- Create a design in cutting software

- Precision-cut design from vinyl

- Weed away excess material

- Layer colors separately

- Fuse design using a heat press

Sublimation Application

- Print full-color transfer directly onto paper

- Trim away margins (no weeding needed)

- Heat and apply the transfer sheet to the product

- Peel paper backing after cooling

As shown above, HTV demands more hands-on effort to slowly assemble than adhere elements. Sublimation condones printing directly onto transfers applied in one seamless motion.

Frequently Asked Questions on Sublimation vs Vinyl

Below are a few frequently asked questions to deepen your understanding:

Which is better vinyl or sublimation?

There’s no definitive “better” option. HTV vinyl offers affordability, versatility, and ease of use for beginners.

Sublimation excels at color precision and permanence but has a steeper learning curve and buy-in costs.

Does sublimation or vinyl last longer?

When properly pressed onto quality blanks, sublimation typically outlasts vinyl in terms of fade and scratch resistance.

Because designs fuse right into the makeup of substrates, they hold up better to repeated laundering and environmental factors over time.

Is vinyl or sublimation better for mugs?

Thanks to its ability to embed graphics within ceramic coatings, sublimation is the preferred process for printing custom mugs.

The results are dishwasher safe and microwave friendly while achieving photorealistic effects not possible by layering vinyl.

Wrapping Up

Deciding between sublimation and vinyl printing comes down to looking at what you need and can do.

If you want affordable short-term projects using everyday materials, beginner-friendly vinyl is good. If you want long-lasting museum-quality prints, sublimation is better for that.

Commercial printers and clothing makers get big rewards from sublimation. It works fast and has excellent color matching. Hobbyists still learning to benefit more from vinyl’s flexibility and low start-up costs though.

No matter which one you pick, always follow the instructions closely. Take good care of your projects after, so they last a long time.

If you find this article useful, please share it with your friends and family!