If you’re into customized goods and quality craftsmanship, you’ve probably heard about sublimation printing.

It’s an amazing process for transferring vibrant designs onto all kinds of surfaces – from fabrics and metals to ceramics and more.

Now I know you probably have more questions, so let’s dive into the nitty-gritty details.

I’ll walk you through everything you need to know about how sublimation works on leather, the preparation process, tips for success, and plenty of inspiring examples along the way.

Let’s get started!

Can You Sublimate On Leather?

So can you really sublimate on leather?

Yes, you totally can!

Sublimating leather has become super popular in the last few years as manufacturers have created products with special coatings that take dye sublimation inks beautifully.

These specially treated leathers have polymer coatings on the surface that allow the sublimation dyes to bond.

When you heat up the inks, they turn to gas and the molecules sink into the polymer coating and fuse there permanently.

It makes a strong bond that lasts, so your printed designs on leather come out looking awesome!

| Leather Variety | Sublimation Feasible? | Reasoning |

|---|---|---|

| Polyurethane (PU) | Yes | The ink bonds well to the plastic-like surface |

| Polyvinyl Chloride | Yes | Can handle the high heat of sublimation |

| Genuine Leather | Yes | Its porous texture absorbs inks |

| Smooth Luxury Leathers | No | Ink tends to wash off over time |

| Vegetable Tanned Leathers | No | Inks don’t absorb well into the hard texture |

How Does Sublimation Work on Leather?

The sublimation process relies on a special ink that turns into a gas when exposed to high heat.

This gas penetrates the coating on the leather and bonds with the material on a molecular level.

When the leather cools, the ink solidifies and becomes a permanent part of the product.

For sublimation to work properly on leather, the material needs to have a polymeric coating that allows the ink to absorb.

Polyurethane and polyvinyl chloride leather tend to work very well for sublimation. The smooth, uniform textures allow for excellent ink transfer.

On the other hand, materials like vegetable tanned leather have a harder surface that makes it difficult for sublimation ink to penetrate properly.

The end result is often a design with poor visibility.

Picking the Perfect Leather for Dye Sublimation

Not all leathers are created equal when it comes to applying gorgeous, detailed designs. Here are some tips on selecting the best varieties for sublimation:

Seeking Out Synthetics

Faux leathers like polyurethane (PU) and polyvinyl chloride (PVC) offer the most flawless, consistent results. Their uniform polymeric finishes readily accept sublimation dyes. These synthetics are also extremely durable – perfect for items prone to wear and tear.

Knowing Natural Leather’s Limitations

Genuine leathers can work beautifully for sublimation, especially on smaller goods like patches, key fobs or guitar straps. But the irregular natural grain makes it trickier for crisp printed details. And some natural leathers have finishes that resist detailed dye infusion.

Remembering That Smoothness is Key

Leathers with a super sleek, glossy finish tend not to hold sublimation ink effectively. The slickness prevents the dye from bonding adequately. So it’s generally best to avoid using very soft, buttery leathers.

Considering Hybrid Options

Some manufacturers now create leathers with synthetic top coats and genuine leather bases. These hybrids offer the best of both worlds – natural feel and look, with a polymer coating for vivid sublimation.

Keep these tips in mind when sourcing leather material for your upcoming projects.

Step-by-Step: How to Sublimate Leather at Home

Once you’ve got your leather picked out, it’s time to start sublimating! Here’s a complete walkthrough of everything involved in printing custom designs at home:

Supplies Needed

- Sublimation printer and ink

- Sublimation transfer paper

- Smooth faux leather cut to size

- Heat press

- Heat resistant tape

- Butcher paper

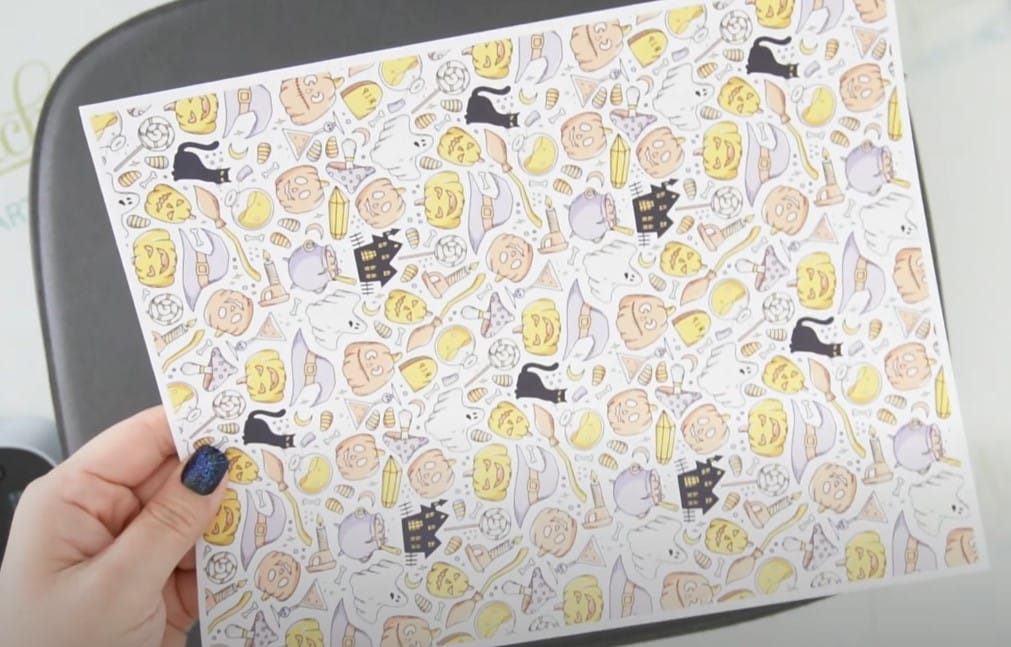

Step 1: Print Design

- Create or obtain the image you want to transfer.

- Print the design onto sublimation transfer paper using a sublimation printer.

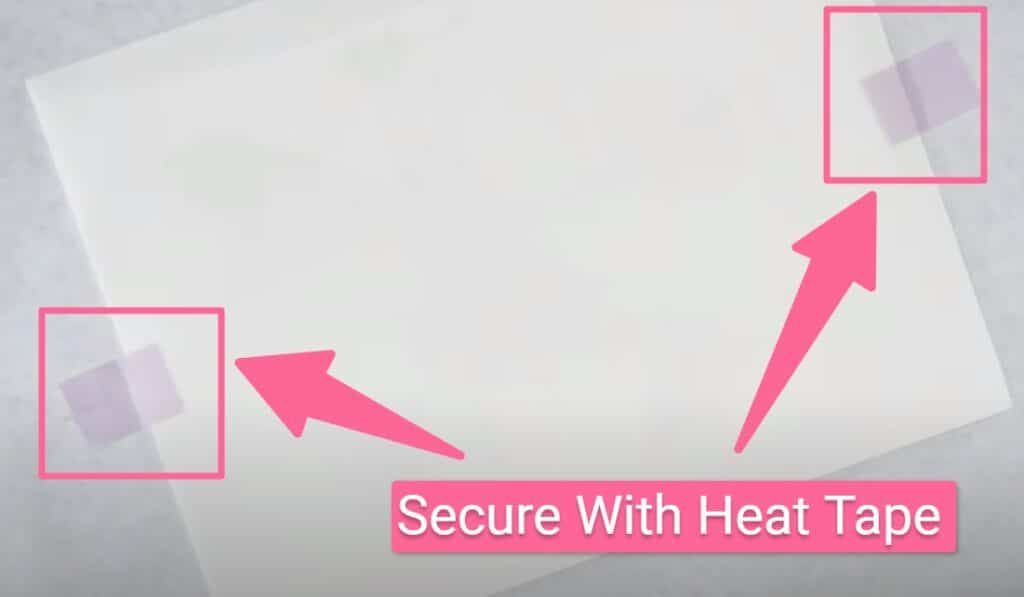

Step 2: Prepare Leather

- Place the faux leather smooth side up on the heat press.

- Place the sublimation vinyl glossy side up on top of the leather.

- Secure it with heat tape

- Cover with butcher paper.

- Press at 395°F for 20 seconds to prepare the leather.

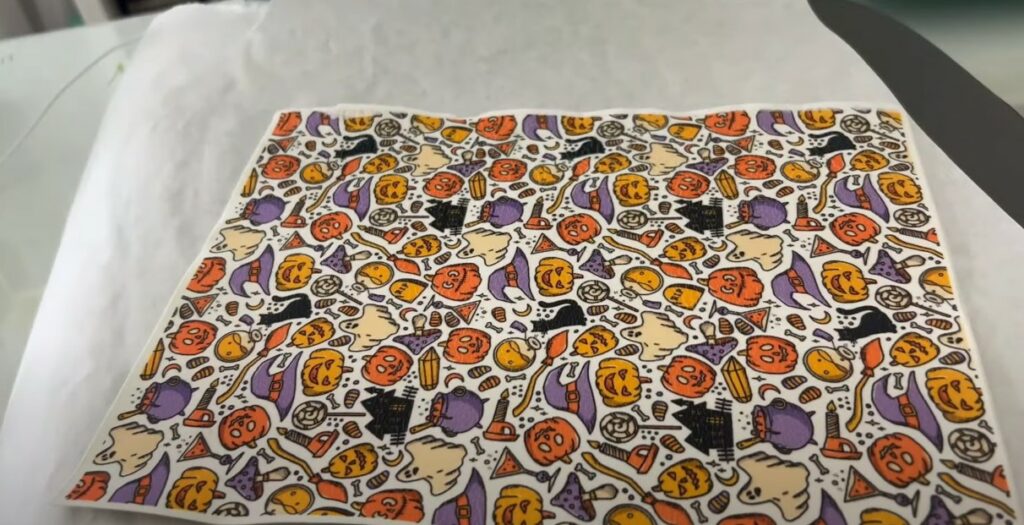

Step 3: Apply Image

- Once cooled, peel off the vinyl carrier sheet.

- Place the printed transfer paper image side down onto the leather.

- Then Cover it with butcher paper

- Press at 375°F for 50 seconds.

- While still warm, remove the transfer paper to reveal the image.

Step 4: Finish

- Your leather piece is complete, now peel off the psublimation paper and reveal the leather.

- The sublimated image should appear vibrant and permanent.

Can you sublimate on faux leather?

Absolutely! Faux leathers like polyurethane and polyvinyl chloride work awesome for sublimation since they have polymer coatings that take the dyes really well.

I’ve made tons of fun custom phone cases and shoes using faux leather blanks. The colors come out super vibrant!

Can you sublimate on polyvinyl chloride leather?

For sure! PVC leather can handle the high heat from pressing without melting, so it’s great for sublimation.

I’ve done duffle bags and backpacks with cool graphic prints using PVC leather since it really holds the ink nicely.

Can you sublimate on genuine leather?

You definitely can! Real leather’s naturally porous surface helps absorb the sublimation inks. I’ve printed fun designs on small genuine leather items like wallets, keychains and wristbands. The natural texture gives a cool look.

Can you sublimate on smooth luxury leathers?

It’s tricky…the super smooth finish makes it hard for the ink to bond tightly.

Any leather conditioners or moisture can make the prints wash off over time.

I tried a luxury leather journal but the print rubbed off quickly.

Can you sublimate on vegetable-tanned leather?

Not really…the rigid texture of vegetable-tanned leather doesn’t absorb much ink, so the prints look faded at best.

I tried to sublimate leather bookmarks and the image was barely visible.

Is Genuine or Synthetic Leather Better?

When it comes to deciding between real and faux leather for sublimation projects, synthetic leather tends to produce better results.

Materials like polyurethane and polyvinyl chloride have consistent textures and thicknesses that allow for smooth ink application.

Genuine leather can work well too, especially for smaller items like patches or keychains. The porous surface helps the ink absorb.

However, the irregular natural grain may impact the clarity of some designs.

Overall, synthetic leather offers a more reliable canvas for sublimation work. It’s also more durable and cost-effective than real leather.

Customizing Different Leather Products with Sublimation

From footwear to accessories, sublimation opens up endless possibilities for customizing leather items.

Here are some of the most common leather goods to embellish with this technique:

1. Sublimation on Leather Shoes

Sneakers and other footwear make a great canvas for dye sub designs.

Just take care to only sublimate shoes made with leather materials suitable for high heat.

Polyurethane leather shoes tend to work very well. Be sure to test a small spot first before pressing the entire shoe.

2. Sublimation on Leather Wallets

Leather wallets, especially those made with polyvinyl chloride, take beautifully to sublimation work.

First, measure the pressing area and secure the wallet so it doesn’t shift during the heat application.

Once pressed, the ink will infuse directly into the leather for stunning, vivid imagery that won’t scratch or peel off.

3. Sublimation on Leather Bags

Totes, purses, backpacks – you name it, leather bags are a versatile option for dye sub.

Sublimation allows for intricately detailed designs that really make the bag unique.

Just take care with thin leathers, as too high heat could damage the material.

4. Sublimation on Leather Jackets

With its high durability and supple feel, leather outerwear is ideal for sublimation’s permanent images.

Jackets made with polyurethane or polyvinyl chloride materials will yield the best results. Be extra careful about precise temperature control to avoid any damage to the leather.

5. Sublimation on Leather Phone Cases

Phone cases are one of the most popular leather items enhanced with sublimation printing.

The process allows for crisp details, vibrant colors, and durable designs that hold up to wear and tear.

Just remember to keep the heat in the optimal 290°-300°F range for best results.

Handy Tips and Tricks

Beyond having the right supplies and techniques, there are some additional pointers to ensure success when sublimating leather:

- Use pre-printed patterns in tandem with custom sublimation for unique keychains, patches, and more.

- Try sublimating on plain faux leather sheets to create products like notebooks or wallets.

- For small genuine leather goods, opt for a printable heat transfer vinyl specially designed for naturals.

- Purchase pre-made leather sublimation blanks like tags or bookmarks for instant, hassle-free projects.

- If you don’t have access to a cutting machine, use sharp scissors or an X-acto knife to trim leather pieces.

- Store sublimated leather items in a cool, dry place away from direct sunlight to preserve the images.

FAQs: Common Sublimation Leather Questions

I get lots of great questions from leather sublimation beginners. Here are answers to some of the most frequent FAQs:

What Happens if the Leather is Overheated?

Excessive heat can actually cause the sublimation inks to break down instead of bonding correctly. This not only ruins the print, but can create harmful chemical byproducts. Precise temperature control is crucial!

What About Recommendations for Sublimation Printers?

Your best bet is a dedicated thermal transfer printer engineered specifically for sublimation work. Top models from Sawgrass, Epson and Ricoh with high heat-tolerant inks produce optimal leather results.

Will Sublimated Leather Designs Fade Over Time?

With quality materials and proper technique, the prints should retain vivid colors and clarity for the life of the leather product itself. But long-term exposure to pollutants, sunlight and wear will cause fading and degradation over time.

What’s Better – Genuine or Faux Leather?

Each has pros and cons. Faux leather offers reliable, consistent print quality batch to batch. But genuine leather provides a high-end feel and often longer lifespan. New hybrid leathers blend the best of both!

I hope these answers help explain some of the most common questions around sublimating on leather!

Let’s Sum Up This Leather Sublimation Journey

Well there you have it – everything you could possibly need to know to start crafting incredible custom leather pieces using the power of sublimation!

While mastering the precise timing, temperatures and techniques involved takes practice, the payoff is so rewarding.

With the right printer, inks, transfer papers and leather blanks, you can create dazzling personalized wallets, boots, pet collars, laptop sleeves and more. Just imagine the possibilities!

I hope this guide provided tons of tips, tricks and inspiration to unlock the creative potential of sublimation printing on leather.

The process lets you make cherished heirloom gifts, striking statement pieces and memorable merchandise creations.

Now that you’re armed with all this knowledge, I can’t wait to see what unique leather goods you’ll sublimate next.

As always, feel free to reach out if you have any other questions as you begin your leather sublimation journey. Let’s see those amazing designs!