Have you ever wanted to add cool designs or images to PVC (polyvinyl chloride) products like bags, mugs, or other plastic items?

You might have thought about using a fun technique called sublimation printing to get that custom look. Sublimation printing uses heat to transfer dye onto materials for bright, long-lasting designs.

In this article, we’ll explore ‘Can you sublimate on PVC?’. We’ll look at the key reasons why PVC may or may not work well with the high heat required for sublimation. You’ll learn about the potential risks of trying this process with PVC.

So, let’s get started!

you may also like:

- Can You Sublimate On Plastic? (Explained!)

- How Do I Make My Sublimation Brighter? Pro Tips

- How Can I Get Better At Sublimation?

- What Is A Sublimation Water Bottle? (Explained!)

can you sublimate on PVC?

The short and straightforward answer is: No, it is not recommended to sublimate on PVC.

While the idea might seem tempting, especially if you have some cool designs in mind, there are several crucial reasons why attempting sublimation on PVC can lead to disappointing results and even potential safety hazards.

Why Sublimating On PVC Is Not Recommended?

As mentioned earlier, sublimation on PVC is not advisable due to the following reasons:

1. Non-porous material

Sublimation relies on dye transfer into the fibers of a material, but PVC is a non-porous plastic lacking the necessary structure for dye absorption.

This means that the dye particles won’t be able to effectively penetrate and bond with the PVC surface.

As a result, you’ll likely experience poor adhesion, which can lead to potential fading, peeling, or cracking of the design over time.

2. Melting and warping

PVC has a relatively low melting point compared to the high temperatures used in sublimation (around 400°F or 204°C).

Exposing PVC to such extreme heat can cause the material to melt, deform, or warp, ruining the appearance and integrity of your project.

This not only wastes your time and effort but can also potentially damage your sublimation equipment, leading to costly repairs or replacements.

3. Fumes and health concerns

When heated excessively, PVC can release harmful fumes, including hydrogen chloride gas, which can be toxic if inhaled in significant quantities.

Proper ventilation is crucial when working with PVC, but even then, the potential health risks associated with these fumes should not be ignored, especially in a crafting or hobby setting where safety should be a top priority.

4. Environmental impact

PVC is a non-biodegradable plastic with a significant environmental footprint. From its production to disposal, PVC can contribute to various environmental issues, such as resource depletion, pollution, and greenhouse gas emissions.

Using it for sublimation goes against sustainable practices and can add to the already concerning plastic waste problem.

As eco-conscious crafters, it’s essential to consider the environmental implications of the materials we use and explore more sustainable alternatives whenever possible.

How to sublimate on PVC

Since sublimation on PVC is not recommended due to the reasons mentioned above, it’s better to explore alternative methods or materials that are more suitable and safer for your projects.

However, if you’re determined to try sublimating on PVC (at your own risk), here are a few general steps you might consider:

1. Prepare the PVC surface

Ensure the PVC surface is clean and free from any contaminants, such as dirt, grease, or residues, that could interfere with the dye transfer.

Use a suitable degreaser or cleaner specifically formulated for PVC surfaces.

2. Adjust the temperature and pressure settings

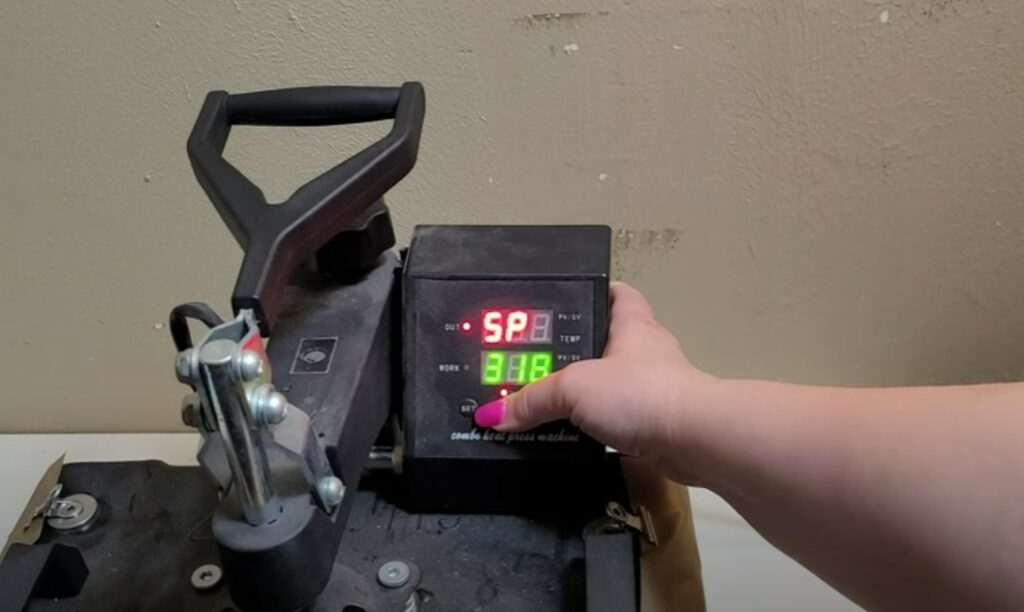

Carefully adjust your sublimation printer’s temperature and pressure settings to avoid melting or warping the PVC material.

This may require some trial and error, as different PVC products can have varying melting points and heat tolerances.

It’s essential to start with lower settings and gradually increase them, monitoring the results closely.

3. Test on a small area

Before committing to a full-scale project, it’s highly recommended to test the sublimation process on a small, inconspicuous area of the PVC material.

This will allow you to assess the results, and potential issues, and make any necessary adjustments before proceeding further.

4. Use proper ventilation

If you decide to proceed with sublimating on PVC, ensure proper ventilation in your workspace.

This could involve using an exhaust fan, opening windows, or even working in a well-ventilated outdoor area. The goal is to minimize the inhalation of harmful fumes that may be released during the heating process.

5. Consider protective equipment

Depending on the extent of your project and the level of fumes produced, it might be wise to wear protective gear, such as a respirator or mask, to further reduce your exposure to potentially harmful vapors.

6. Monitor the process closely

During the sublimation process, keep a close eye on the PVC material to detect any signs of melting, warping, or other issues.

If you notice any concerning changes, stop the process immediately to prevent further damage or safety risks.

What are the Alternatives to PVC

Instead of risking suboptimal results, potential hazards, or environmental concerns associated with sublimating on PVC, it’s highly recommended to explore these alternative options for your sublimation projects:

1. Screen printing

Screen printing is a more reliable and durable option for printing on PVC materials, although it requires specific equipment and expertise.

In this process, ink is forced through a mesh screen onto the PVC surface, creating a long-lasting and vibrant print.

While it may have a higher initial investment, screen printing can produce professional-quality results and is well-suited for larger quantities or complex designs.

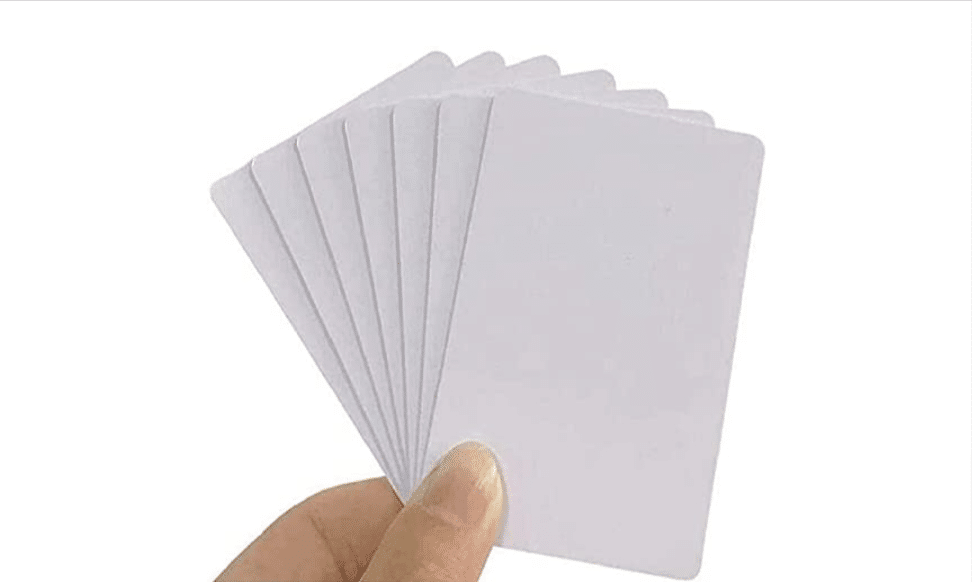

2. Vinyl stickers

Pre-printed vinyl stickers designed specifically for PVC surfaces are a practical and readily available solution.

These stickers are made from a durable, weather-resistant material that adheres well to PVC, providing a long-lasting and visually appealing result.

They are available in various sizes, colors, and designs, making them a versatile option for customizing PVC products.

3. Direct printing services

Some companies offer specialized direct printing services on PVC products, which might be suitable for large quantities or complex designs.

These services typically use industrial-grade printers and inks specifically formulated for PVC, ensuring high-quality and durable results.

While this option may be more expensive, it can be a convenient solution for those with limited access to specialized equipment or expertise.

When selecting an alternative method or material, it’s essential to weigh factors such as cost, equipment requirements, desired durability, and the specific requirements of your project.

Frequently asked questions

Below are a few frequently asked questions:

What kind of plastic can you sublimate on?

Sublimation works best on polymers with a porous structure, such as polyester, polyester-coated materials, and certain types of coated substrates.

Plastics like PVC, which are non-porous, are generally not suitable for sublimation.

Is PVC sensitive to heat?

Yes, PVC is sensitive to heat. It has a relatively low melting point compared to the high temperatures used in sublimation (around 400°F).

Exposing PVC to such high temperatures can cause it to melt, warp, or release harmful fumes.

What can you not sublimate on?

While sublimation can be used on various materials, certain surfaces are not suitable for this technique.

Materials you should avoid sublimating on include mon-porous plastics (like PVC), glass, metal, uncoated ceramics, and leather.

Wrapping up

In conclusion, while the idea of sublimating on PVC might seem appealing, it’s crucial to understand the limitations and potential risks associated with this process.

PVC’s non-porous nature, low melting point, and potential for releasing harmful fumes make it an unsuitable material for successful and safe sublimation.

Instead of risking sub-optimal results or compromising safety, it’s recommended to explore alternative printing methods like screen printing or vinyl stickers for PVC projects.

Remember, your safety and the quality of your projects should always take precedence.

By making informed decisions and utilizing the right materials and techniques, you can bring your creative visions to life while ensuring a hassle-free and enjoyable crafting experience.