Have you ever wondered how those cool t-shirts with vibrant designs are made?

In this article, we’ll learn everything about screen printing — outlining each step, highlighting its many benefits, and even sharing some historical context.

We’ll be answering all these questions:

- What is screen printing?

- History of screen printing

- A step-by-step process for screen printing

- Advantages of screen printing

- Comparisons with other printing techniques

If you’re curious about the artistry behind printed fabrics or promotional materials, read on to have all your questions answered!

Key Takeaways

What Is Screen Printing

So, screen printing is this cool printing technique where you can transfer your design onto different things like t-shirts, posters, or even coffee mugs.

Basically, you create a stencil of your design on a mesh screen, usually made of silk or synthetic fibers.

Then, you apply a light-sensitive emulsion on the screen and let it dry.

Once it’s dry, you place the screen on top of the material you want to print on and secure it with a press.

Next, you pour some ink on the screen and use a squeegee to push the ink through the mesh screen and onto the material.

The ink will only pass through the areas where the design is, creating a nice, crisp print.

History Of Screen Printing

Screen printing is a time-honored craft that traces its roots back to ancient China during the 10th century.

In those early days, the Chinese artisans employed silk, paper stencils, and mesh screens made from human hair to transfer intricate designs onto fabric.

The art of screen printing also found its way to Japan, where simple stenciling techniques were used to adorn textiles.

The introduction of screen printing to Western Europe from Asia occurred in the late 18th century.

However, it took some time for the technique to gain widespread acceptance and usage in Europe.

The availability of silk mesh for trade from the East and the discovery of profitable applications for this medium were key factors in its growing popularity.

In 1907, a noteworthy Englishman by the name of Samuel Simon obtained a patent for the first “modern” screen printing system.

Simon’s system involved the use of a stencil carefully drawn onto bolting cloth, which was then stretched across a wooden frame.

Initially, screen printing was primarily employed to add vibrant colors and captivating patterns to wallpaper and fabrics.

Gradually, advertisers recognized its potential and began utilizing it for promotional campaigns.

Over time, artists and commercial printers alike embraced screen printing as an innovative method to reproduce their works on various materials such as t-shirts, DVDs, glass, paper, metal, and wood.

Today, screen printing has become a prevalent technique for creating mass-produced or large-batch graphics, including posters and display stands.

The Process of Screen Printing

To start the screen printing process, a stencil is created on a mesh screen, onto which ink is applied and transferred onto the surface to create the desired design.

1. Creating a stencil on a mesh screen

Screen printing starts with the creation of a stencil on a mesh screen. Let’s explore how this is done:

- Get the right mesh screen: Pick a fine mesh screen made of materials like silk or synthetic stuff (terylene rocks!). Stretch it tight and attach it to a cool metal or wooden frame.

- Get the screen ready: Take that mesh screen and coat it up with some light-reactive emulsion using a scoop coater (fancy metal trough with a clean edge). Spread that emulsion evenly all over the screen.

- Time to design: Get creative! Print your design on a transparent acetate film or use other cool methods like hand-drawing with opaque ink, printing on transparency, or cutting out some rad rubylith (it’s like an ultraviolet-masking film).

- Expose To Bright Light: Put your design against the coated screen and expose it to some bright light. The light will harden the emulsion in the areas not covered by the design, creating a stencil

- Rinse it off: After the exposure, rinse the screen with water to wash away any unhardened emulsion, leaving your awesome design clear and crisp on the screen.

- Time to dry: Let the screen dry completely before you move on to the printing process.

Read this in-depth guide on DIY Silk Screen Stencil Tutorial

Or watch this video tutorial:

2. Applying ink to the screen and transferring it onto the surface

After you have your stencil ready, you can now move forward towards the printing process:

- Set up your printing station: Place the screen above the object or surface you want to print on. Make sure you have a solid printing board or surface underneath to support your material.

- Apply The Ink: Pour some ink onto the screen, right above the design area. Take a trusty squeegee and spread that ink evenly and with a bit of pressure across the screen. You want that ink to stick!

- Print The Design: Lower the screen onto your object or surface, making sure everything lines up perfectly. Then, use the squeegee to press the ink from the screen onto your material. Apply steady and even pressure to get that perfect print you’re after.

- Repeat the process: If you’re printing on multiple objects, move on to the next one. Just position it under the screen and repeat steps 2 and 3. Ensure proper alignment and ink application for each print

3. Drying and curing the printed design

In screen printing, drying and curing the printed design is a critical part of the process. Here’s how it works:

- Once the ink has been transferred onto your chosen surface through the mesh screen, it needs to dry.

- This involves passing the freshly printed product through a dryer or conveyor tunnel equipped with heating elements.

- A crucial step that ensures a seamless finish, it ‘cures’ the ink creating durable colorfast graphics.

- The temperature for curing usually ranges between 320 and 360 degrees Fahrenheit depending on different types of ink used and material being printed on.

- Not all items can tolerate high temperatures; in such cases, low-cure or cold-cure inks are utilized.

- Remember to ensure that both sides of your item are heated evenly to avoid any warping or distortion in the final product.

- Flash dryers are often used for this purpose as they provide focused, direct heat perfect for curing prints quickly and efficiently.

- As soon as the curing process finishes, it is essential to thoroughly clean the screen to remove any remaining ink or residue

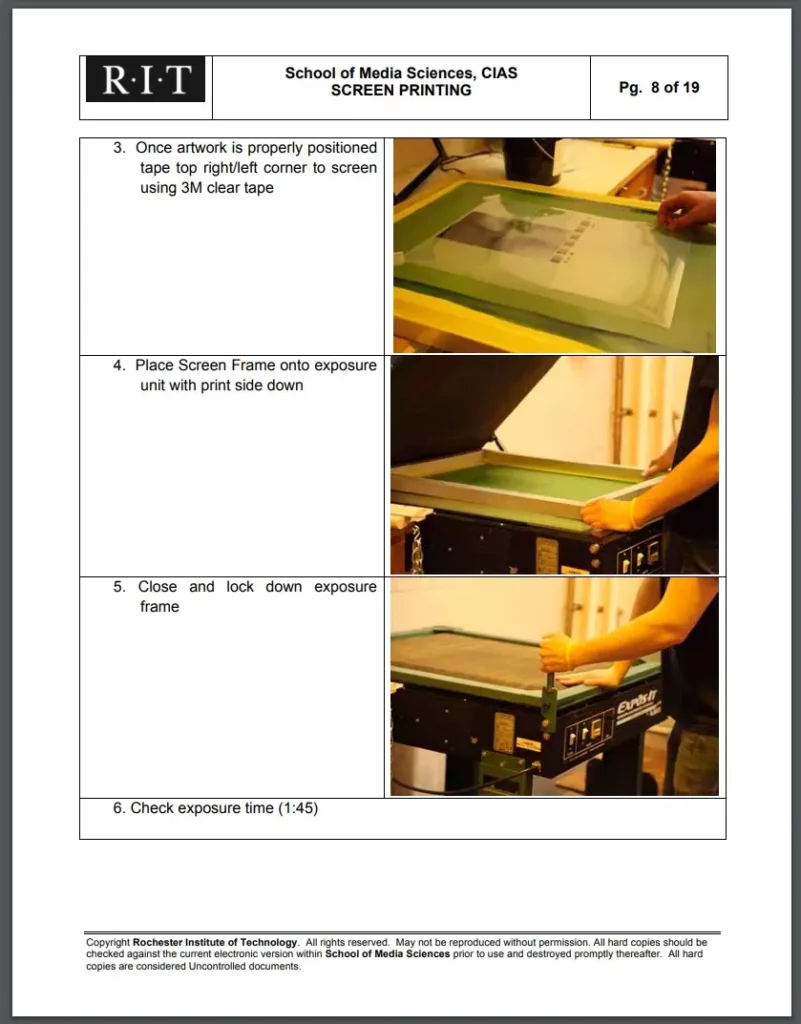

Screen printing process step by step pdf

Download this amazing step by step PDF guide on screen printing process by Rochester Insititute Of Technology.

This is an in depth guide on screen printing with steps and images.

Advantages of Screen Printing

Screen printing offers versatility in materials and surfaces, long-lasting and durable prints, vibrant and opaque colors, cost-effective bulk production, as well as customization and intricate details in designs.

1. Versatility in materials and surfaces for printing

Screen printing offers remarkable versatility when it comes to the materials and surfaces that can be printed on. Whether you’re DIYing at home or looking to start a small business, screen printing allows you to print on various surfaces like fabric, paper, glass, wood, and even card.

This means you can personalize t-shirts, create unique art prints, design eye-catching signage or promotional products – the possibilities are endless!

With screen printing, you have the freedom to explore different mediums and unleash your creativity without limitations.

Plus, with the right techniques and tools in hand – such as mesh screens and specialized inks – you can achieve professional-looking results every time.

2. Long-lasting and durable prints

Screen printing is well-known for its ability to create long-lasting and durable prints. This printing method involves applying a thick layer of ink onto the surface, resulting in designs that can withstand wear and tear.

Unlike other printing methods, screen printing provides heavy ink coverage, ensuring that the colors stay vibrant even after repeated washing or exposure to the elements. Whether you’re printing on clothing, accessories, signage, or promotional materials, screen printed designs are built to last.

That’s why it’s a popular choice among artists and DIYerslooking for high-quality and resilient prints that will stand the test of time.

3. Vibrant and opaque colors

Screen printing is a fantastic method for achieving vibrant and opaque colors in your designs. Unlike other printing techniques, screen printing allows you to use multiple colors separately, ensuring that each color stands out boldly on its own.

The process involves applying ink through a stencil or mesh onto the surface being printed, resulting in rich and intense shades. These vivid and bolder colors are difficult to replicate using other methods, making screen printing the go-to choice for creating eye-catching prints.

4. Cost-effective

Screen printing becomes increasingly cost-effective as the production volume increases. Once the setup is complete, the cost per unit decreases significantly for each additional item printed. This makes it ideal for large quantities of the same design.

Additionally, the materials used in screen printing, such as screens, inks, and emulsions, are relatively inexpensive, especially when compared to other printing methods. This helps keep the overall production costs down, especially for bulk orders.

Applications and Uses of Screen Printing

Screen printing has a wide range of applications, including clothing and apparel, promotional products and merchandise, signage and banners, as well as art and graphic prints.

1. Clothing and apparel

Screen printing is widely used in the clothing and apparel industry to print designs on various types of fabrics. With screen printing, you can create custom t-shirts, hoodies, or hats with your own unique designs.

The process allows for intricate details and vibrant colors that won’t fade over time. Screen printing also offers durability, ensuring that your printed design will withstand regular wear and washing.

This makes it an ideal choice for creating personalized garments or merchandise for yourself or your business. Plus, screen printing is cost-effective when producing in bulk, making it a popular technique among DIYers looking to start their own clothing line or create one-of-a-kind items.

2. Promotional products and merchandise

Promotional products and merchandise are a key application of screen printing. This versatile printing technique allows businesses to create custom designs on various items, such as T-shirts, hats, bags, pens, and more.

Screen printing offers vibrant and long-lasting prints that can effectively showcase brand logos or messages. With the ability to print in large quantities at a low cost, screen printing is an ideal choice for promotional campaigns or events where multiple items need to be imprinted with the same design.

Whether it’s giving away branded merchandise at trade shows or creating custom apparel for employees or customers, screen printing ensures that your promotional products make a lasting impression.

3. Signage and banners

Screen printing is a versatile technique that is commonly used for creating signage and banners. It allows for vibrant and bold colors to be printed onto various materials, making it ideal for outdoor displays.

With screen printing, you can produce custom signage and banners with great details and precise placement of the design.

This ensures durability and longevity of the printed designs, as well as the flexibility to print on different types of substrates like fabric, metal, plastic, or paper. Whether you need promotional banners for your business or eye-catching signs for an event, screen printing offers a cost-effective solution that produces high-quality results.

4. Art and graphic prints

Screen printing is a popular technique for creating stunning art and graphic prints. With this method, DIYers can easily replicate intricate designs onto various surfaces like paper, fabric, metal, wood, or plastic.

The screen printing process allows for precise details and vibrant colors to be transferred onto the final product. Whether you’re looking to create unique wall art or eye-catching posters, screen printing offers a versatile and cost-effective solution.

Plus, the durability of screen printed designs ensures that your artwork will last for years to come.

Comparison: Screen Printing vs. Digital Printing

Screen printing and digital printing are two popular techniques that are often used for creating designs on various materials.

While they both have their advantages and disadvantages, the choice between the two often depends on the specific requirements of the project.

Here is a comparison of screen printing versus digital printing:

| Screen Printing | Digital Printing | |

|---|---|---|

| Process | Screen printing involves creating a stencil on a mesh screen, then pushing the ink to create and imprint the design on a flat surface. It’s done one color at a time. | Digital printing is a direct-to-garment process that involves transferring a design onto fabric through the use of inks that are directly infused into the fibers of the material. These presses usually produce a full 4-color process print. |

| Workflow | Screen printing requires numerous steps and a considerable amount of preparation before the printing can begin. | Digital printing processes are simpler and faster, saving numerous steps compared to screen printing. |

| Quality & Durability | Screen printing produces high-quality, durable prints and allows for precise color matching. This technique is often used in textile printing processes due to its durability. | Digital printing offers flexibility in terms of design customization. However, it is less durable compared to screen printing. |

| Cost Effectiveness & Speed | Screen printing is more economical for larger quantities. Its process though is more time intensive compared to digital printing. | Digital printing is faster and more cost-effective for small quantities. Its speed and economy make it an advantageous option for smaller print runs. |

These differences between screen and digital printing make each method suitable for different types of projects. Choosing the right method often depends on the specific requirements and budget of each project.

Comparison: Screen Printing vs. Heat Transfer

Screen printing and heat transfer are two popular techniques for printing designs on textiles and other materials. Let’s compare these two methods in terms of process, cost, complexity, durability, and quality.

| Screen Printing | Heat Transfer | |

|---|---|---|

| Process | Requires creating a stencil and applying ink through the stencil onto the surface. This is done one color at a time. | Uses heat to transfer a design from a special type of paper to the desired surface. Full-color images can be transferred at once. |

| Cost | More cost-effective for bulk production due to the setup cost. | Suitable for small quantity orders as there is no setup cost. However, the cost per unit can be high. |

| Complexity | Complex process that requires skill and practice. It’s often automated in the industry to streamline the process. | Simpler process, making it more suitable for DIYers. |

| Durability | Known for long-lasting and durable prints that can withstand many washes. | Less durable than screen printing, but advancements in technology are improving the longevity of heat transferred prints. |

| Quality | Results in vibrant, opaque colors and allows for intricate details in designs. | Can achieve high detail, but the color vibrancy may be lower than in screen printing. |

This comparison between screen printing and heat transfer can guide you in selecting the right technique for your project, considering aspects like quantity, design complexity, and durability requirements.

FAQs

1. Do Screen-Printed Shirts Last?

Screen-printed shirts are generally long-lasting and durable if they are taken care of properly.

The durability of screen-printed shirts depends on factors such as the quality of the ink used, the washing and drying methods, and the frequency of use. High-quality screen printing inks can last for years if the shirts are well-maintained

2. Is Screen Printing Good Quality?

Yes, screen printing is generally considered to be a high-quality printing method. It allows for vibrant colors, excellent color saturation, and durable prints that maintain their quality over time.

3. What Are The Benefits Of Using Screen Printing?

Screen printing offers several advantages including durability and longevity of prints, vibrant colors with excellent opacity even on dark fabrics or surfaces, versatility in terms of materials it can be used on (fabric, paper, glass), and cost-effectiveness for large production runs.

4. Can I Do Screen Printing At Home?

Yes! While professional-grade equipment may be required for high-quality results in commercial settings,

screen printing can also be done at home with affordable DIY kits that include everything you need such as screens, inks, and squeegees.

However, it’s important to note that achieving consistent results may require practice and experiment with different techniques

Final Words

So we have came to the end, screen printing is a versatile and cost-effective method for transferring designs onto various surfaces.

By following a step-by-step process of creating stencils on mesh screens, applying ink, and curing the prints, you can achieve vibrant and durable results.

With its ability to print on different materials and its long-lasting properties, screen printing is an ideal choice for DIYers looking to create customized clothing, promotional items, signage, or art prints.

Explore the world of screen printing and unlock your creativity today!