Sublimation is a popular printing technique that allows you to transfer a design onto a substrate using heat and pressure.

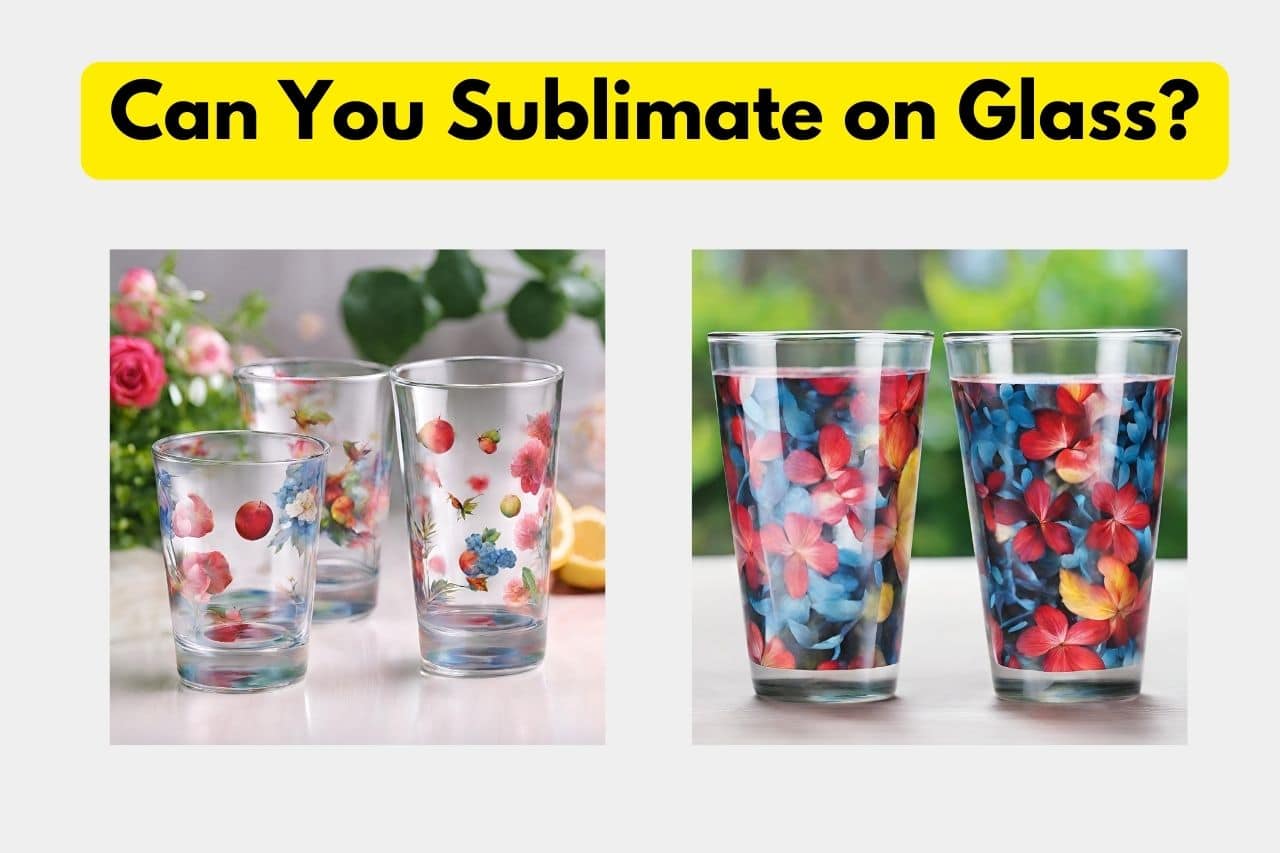

While sublimation is commonly used on fabrics and ceramics, you may be wondering “Can You Sublimate on Glass”.

The short answer is yes, you can sublimate on glass, but there are a few things you need to know before you get started.

First and foremost, not all types of glass are suitable for sublimation. Glass needs to have a special coating that is designed to receive sublimation inks.

This coating is often applied to glass products that are specifically designed for sublimation, such as glass cutting boards, coasters, and ornaments.

Without this coating, the sublimation ink will not adhere to the glass, and you will not get the desired results.

Can You Sublimate On Glass?

If you’re wondering whether you can sublimate on glass, the answer is yes!

However, not all types of glass are suitable for sublimation.

Glass needs to have a special coating that is designed to receive sublimation inks. This coating is often applied to glass products that are specifically designed for sublimation.

To sublimate on glass, you will need a few things:

- A heat press

- Sublimation ink

- Sublimation paper

- Heat-resistant glass with a polyester or vinyl sublimation coating

- Teflon sheet

Once you have these items, you can start the sublimation process. First, print your design onto the sublimation paper. Make sure that it is printed with the actual picture configuration and not reverse-printed.

Next, carefully tape the printed paper to the glass blank and place it on a Teflon sheet in the heat press to protect it from any wear and tear.

Heat the press to the appropriate temperature and press for the recommended time.

After the sublimation process is complete, remove the glass from the press and let it cool. Once it has cooled, remove the sublimation paper carefully.

Your design should now be permanently sublimated onto the glass.

With the right materials and equipment, sublimating on glass can be a great way to create unique and personalized items.

Whether you’re looking to create custom glassware or add a special touch to your home decor, sublimating on glass can be a fun and rewarding process.

Preparing Glass for Sublimation

Before you can start sublimating on glass, you need to prepare the glass surface for sublimation. This involves cleaning the glass and applying sublimation coating. Here are the steps to prepare the glass for sublimation.

1. Cleaning the Glass

The first step in preparing glass for sublimation is cleaning the glass. You want to make sure the glass is free from any dirt, dust, or fingerprints. This will ensure that the sublimation ink adheres to the glass surface properly.

To clean the glass, you can use a lint-free cloth and a cleaning solution. You can use a commercial glass cleaner or make a DIY cleaning solution using equal parts water and vinegar.

Spray the cleaning solution onto the glass surface and wipe it clean with the lint-free cloth. Make sure the glass is completely dry before proceeding to the next step.

2. Applying Sublimation Coating

The next step in preparing glass for sublimation is applying sublimation coating. Sublimation coating is a special coating that allows sublimation ink to adhere to the glass surface.

You can use SubliGlaze sublimation Coating for that purpose.

To apply sublimation coating, you can use a spray bottle or a brush. Make sure the glass is completely dry before applying the sublimation coating.

Apply a thin, even layer of sublimation coating to the glass surface. Let it dry completely before proceeding to the next step.

Once you have cleaned the glass and applied sublimation coating, you are ready to start sublimating on glass. Remember to handle the glass with care to avoid scratching or damaging the surface.

Sublimation Process Overview

Sublimating on glass is a simple process that involves printing a design on sublimation paper and then transferring the image onto a glass surface using heat and pressure. Here is an overview of the sublimation process:

1. Printing the Design

The first step in sublimating on glass is to print your design on sublimation paper. Make sure that the image is printed in the actual picture configuration and not reverse printed.

This is important because the image will be transferred onto the glass surface in the same orientation as it appears on the paper.

2. Transferring the Image

After printing, tape the printed paper to the glass blank carefully and place it on a Teflon sheet in the heat press to protect it from any wear and tear.

Set the temperature and time on the heat press according to the type of glass and sublimation ink being used.

Once the heat press is ready, place the glass blank with the sublimation paper facing down on the Teflon sheet and press it for the required time.

Once the sublimation process is complete, remove the glass blank from the heat press and remove the sublimation paper. Your design will now be transferred onto the glass surface.

It is important to note that not all types of glass can be sublimated on. Glass needs to have a special coating that is designed to receive sublimation inks.

This coating is often applied to glass products that are specifically designed for sublimation.

Finishing and Preservation

Once you have sublimated your design onto the glass, there are a few things you can do to ensure the longevity of the product. Here are some tips on how to finish and preserve your sublimated glass:

1. Curing the Sublimated Glass

Curing the glass is an important step in ensuring that the sublimated design lasts as long as possible.

The curing process involves heating the glass to a high temperature, which helps the ink to bond with the surface of the glass. This process also helps to prevent the ink from fading or peeling off over time.

To cure the glass, you can use either a heat press or an oven. If you are using a heat press, place the sublimated glass face down onto the press and apply heat for 10-15 minutes at 400°F.

If you are using an oven, place the sublimated glass onto a baking sheet and bake for 10-15 minutes at 400°F.

2. Maintenance Tips

To ensure that your sublimated glass stays looking its best, there are some simple maintenance tips that you can follow:

- Avoid using abrasive cleaners or scrubbers on the glass, as this can scratch the surface and damage the sublimated design.

- Hand wash the glass with a mild detergent and warm water. Avoid putting the glass in the dishwasher, as the high temperature and harsh detergents can damage the sublimated design.

- Store the glass in a cool, dry place away from direct sunlight. Exposure to sunlight can cause the ink to fade over time.

- If you need to transport the glass, wrap it in a soft cloth or bubble wrap to protect the sublimated design from scratches and damage.

By following these simple steps, you can ensure that your sublimated glass stays looking great for years to come.

Troubleshooting Common Issues

Sublimating on glass can be a bit tricky at times, and you may encounter some issues while doing so. Here are some common problems you may face and how to troubleshoot them:

Image Clarity Problems

One of the most common issues that you may face while sublimating on glass is image clarity problems. This can happen if you do not use the right settings or if the glass is not clean enough. To avoid this issue, make sure that you use the correct settings for your sublimation printer and ensure that the glass surface is clean.

You can clean the glass with a lint-free cloth and some isopropyl alcohol. Make sure that the glass is completely dry before you start sublimating. Additionally, you may also want to use a glass cleaner to ensure that there are no smudges or fingerprints on the surface.

Durability Concerns

Another issue that you may face while sublimating on glass is durability concerns. Sublimation on glass is not as durable as sublimation on other materials such as metal or ceramic.

This is because glass is a porous material, which means that the ink can start to fade or wear off over time.

To ensure that your sublimation on glass lasts as long as possible, you should avoid using harsh chemicals or abrasive cleaners on the surface. Additionally, you may want to consider using a clear coat or sealant to protect the image.

This will help to prevent the ink from fading or wearing off over time.

Overall, sublimating on glass can be a bit tricky, but with the right tools and techniques, you can create some beautiful and unique designs. Just make sure that you troubleshoot any issues that you may encounter along the way, and take the necessary steps to ensure that your sublimation on glass lasts as long as possible.