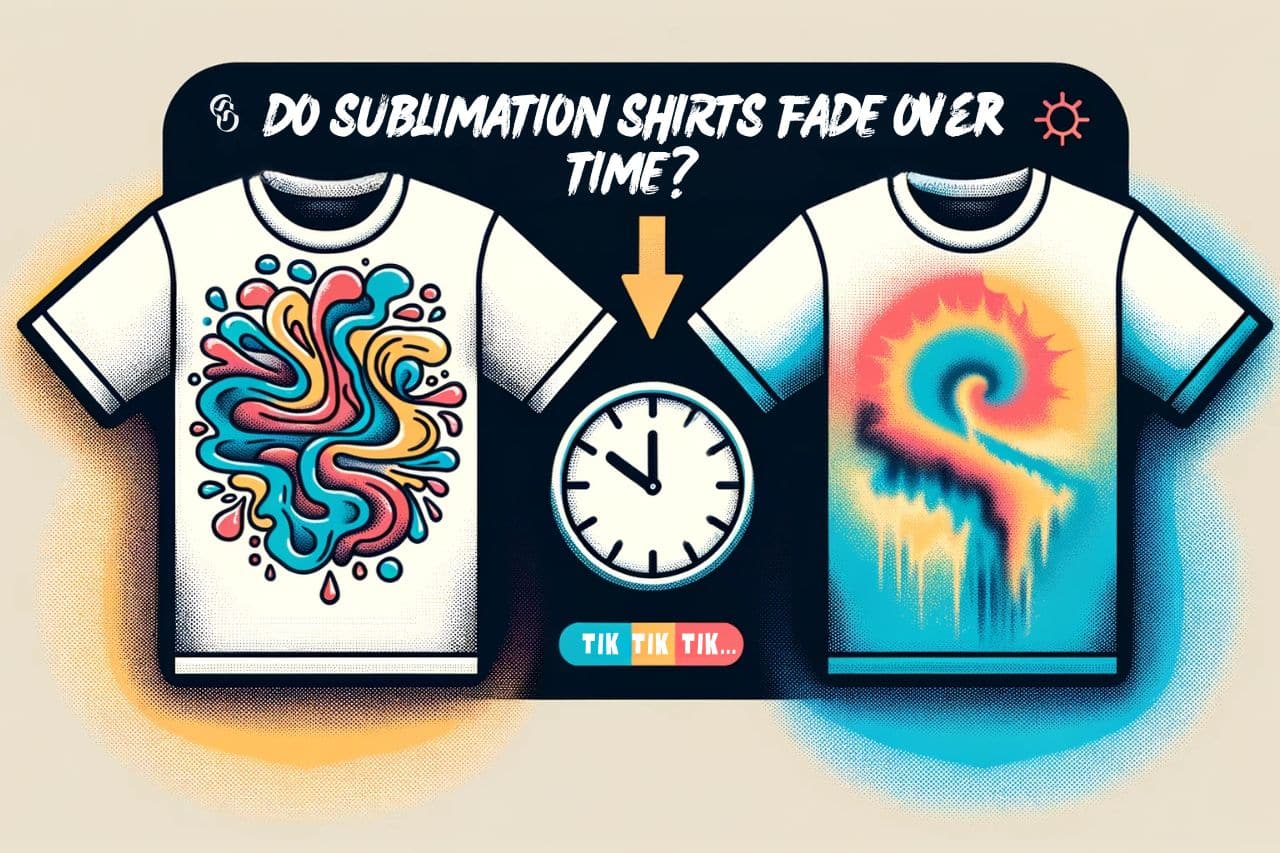

Sublimation printing has become one of the most popular techniques for customizing t-shirts, apparel, and other fabric items. The ability to print professional, full-color designs directly onto fabric makes sublimation incredibly appealing.

However, some people are concerned about whether sublimation prints will fade over time, especially after repeated washing.

In this article, we’ll take an in-depth look at the question – do sublimation shirts fade? We’ll discuss the reasons prints may fade, tips to prevent fading, and what to expect long-term from sublimation prints.

Do Sublimation Shirts Fade?

The short answer is yes, they can eventually fade a bit.

When you wash the shirt, the ink can start to break down and mix with the water, causing it to fade slowly. If you’re washing the shirt a ton or using boiling water, that fading is going to happen faster. Leaving the shirt out in direct sunlight can also make those colors fade quicker thanks to the UV rays.

But there are some things you can do to help your sublimation prints last as long as possible. Try to avoid over-washing the shirt, stick to cold or warm water, and skip the harsh detergents.

Also, don’t leave the shirt to dry in direct sun – dry it in the shade.

And use that sublimation ink on white polyester shirts for your best results.

If you take care of the shirt properly and avoid too much sun and washing, those sublimation prints can look awesome for a really long time.

A little fading over years of wear is normal, but with some easy maintenance, you can keep that color vibrant wash after wash.

Why Are My Sublimation Prints Fading?

Below are the common causes of sublimation print fading:

1. Frequent Washing

One of the biggest contributors to fading is how often the printed item is washed.

Each wash can slowly degrade and pull out sublimation dye from the fabric. The more washes, the more chances for ink to fade.

Washing in hot or warm water is harder on prints than cold water. And harsh detergents containing bleach or chemicals designed to “brighten” or remove stains will strip ink faster.

The mechanical action of washing also rubs prints and causes abrasion.

2. Sunlight Exposure

The UV radiation from sunlight will quickly break down sublimation dyes. This photodegradation causes the prints to lose vibrancy and fade at an accelerated rate. The more sun exposure, the faster fading will occur.

Even indirect sunlight coming through a window can fade prints over time. Drying items in direct sun after washing is especially damaging.

3. Low-Quality Materials

For the ink to optimally bond with fabric, high-quality materials are a must.

Poor quality sublimation paper with an inferior polymer coating will not release and transfer ink well to the fabric.

Low-grade sublimation inks may have poor lightfastness and less ability to withstand washing.

Low-quality printers can cause clogs, resulting in light ink coverage and banding.

4. Improper Heat Pressing

Sublimation requires a heat press to convert ink to gas and bond it with the polymer fibers in polyester fabric.

Time, temperature, and pressure must be properly calibrated.

Too low a temperature or too little pressing time doesn’t allow the sublimation process to be fully complete. This leads to poor ink bonding and fading.

5. Fabric Type

The ink in sublimation printing bonds optimally with polyester fabrics. Natural fibers like cotton lack pores for the ink to sink into.

A polymer coating helps sublimate cotton but it still fades faster than polyester.

Darker fabrics don’t show vibrant colors as well. Over time the weaker ink contrast on darker shades will fade more noticeably than on white or light colored fabrics.

6. Harsh Conditions

Exposure to chlorine, salt water, abrasion, or other harsh conditions will degrade sublimated prints faster than normal wear and care.

Some fading is unavoidable in demanding environments.

Tips for preventing sublimation print fading:

Below are the tips that use can use to prevent sublimation print fading:

1. Wash Less Frequently

The number one thing you can do is limit the washing of sublimated items as much as possible. Only wash when truly needed. The less contact with water and detergent, the better.

2. Wash in Cold Water

Always use the coldest water setting on your washing machine for sublimated apparel. Warm or hot water accelerates fading. Cold water is gentlest on prints.

3. Avoid Harsh Detergents

Never use detergents with additives like bleach, optical brighteners or whiteners. They strip dye. Stick to mild liquid detergents free of dyes, brighteners, and perfumes.

4. Dry Out of Sunlight

Don’t hang or lay sublimated fabrics in direct sun to dry. The UV rays will rapidly fade dyes. Dry items in the shade or use a dryer if needed.

5. Limit Sun Exposure

When wearing or storing sublimated items, keep them away from prolonged direct sunlight as much as possible. Cover car seats, use umbrellas, etc.

6. Proper Storage

Keep sublimated items in a drawer, closet, or box when not in use. Fold carefully to avoid creasing the prints. Acid-free tissue paper between folds can prevent abrasion.

7. Quality Materials

Buy the highest quality sublimation ink, paper, and printer you can. Quality ink resists fading better. Good paper improves ink transfer. A quality printer prevents print defects.

8. Follow Fabric Care Tips

Look for the manufacturer’s fabric care instructions and follow them. Many recommend washing inside-out, gentle cycles, hang drying, etc.

9. Press at Proper Settings

Closely follow recommendations for time, temperature, and pressure when heat pressing. Too little can prevent ink from properly bonding.

10. Allow Prints to Dry

Let sublimated items completely dry after removing them from the heat press before washing or wearing them to prevent dye loss.

How Fabric Choice Impacts Fading

An important factor in sublimation print fading is the actual fabric used for printing. Some fabrics hold up better over time than others.

Polyester Is Best

For the most fade-resistant results, 100% polyester fabric is the best choice.

When polyester is heated during sublimation, the pores in the fabric open up. This allows the dye to fully permeate the fabric and bond permanently at a molecular level.

Polyester blends with at least 60% polyester content will work, but may show fading sooner than 100% polyester.

Cotton Can Be Tricky

Natural fabrics like cotton can be more problematic for sublimation. Cotton lacks the pores to absorb dyes. Usually, a polymer coating is required to bond ink to the surface.

Even with a coating, cotton tends to fade faster than polyester because the ink bonds differently with the fibers rather than absorbing directly into the fabric.

Light Fabrics Hold Color Better

White or very light-colored fabrics produce the best sublimation prints. The ink shows up brightly against the light background.

But over time, the dyes will appear more muted on darker-colored shirts. Red ink on a black tee will fade more rapidly than on a white tee because of the lower contrast.

For longest-lasting prints, go with white or light polyester tees.

Wrapping up

The bottom line – with some reasonable care and handling, sublimation is capable of extremely long-lasting, vibrant prints.

Avoid over-washing, choose the right fabric, keep it out of direct sunlight, and educate your customers on caring for their prints. Set realistic expectations – mild fading over many years is normal and expected.

But compared to other textile printing methods, sublimation really shines when it comes to color-fastness and durability. The extra effort is well worth it for custom apparel that your customers will love wearing for years to come!

So don’t let fears of fading stop you from taking advantage of this innovative, high-quality textile printing technology. Just use quality supplies, dial in your process, and handle the finished products with care. Your custom sublimated apparel will stay looking great wash after wash!