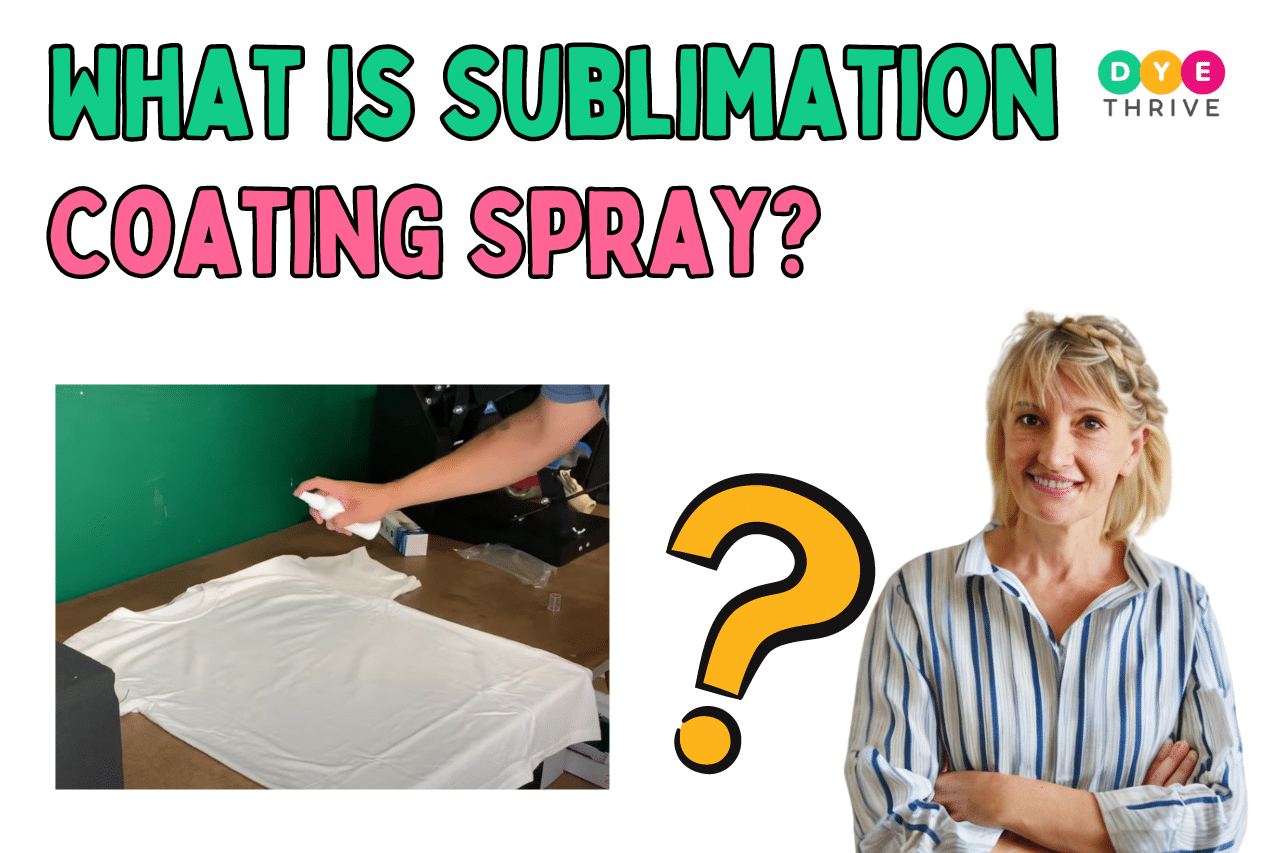

Do you love the vibrant, permanent colors of sublimation printing? Have you ever wished you could use sublimation on regular cotton shirts or other non-polyester substrates?

Well, sublimation coating spray makes this possible!

Sublimation coating spray lets you turn ordinary items like cotton t-shirts, ceramic mugs, wood coasters, and more into sublimation-ready surfaces.

With just a few spritzes of spray, you can unlock the full potential of your sublimation printer.

This guide will cover everything you need to know about sublimation coating sprays. You’ll learn what it is, how to apply it properly, tips for getting great results, and even how it holds up over time.

Whether you’re just starting with sublimation or looking to expand what you can print on, this guide has you covered. Let’s dive in!

You May Also Like:

- Can You Sublimate On Cardstock? (Yes You Can But….)

- Are Sublimation Mugs Microwave Safe? (Yes, They Are But..)

- Why is Black Sublimation Turning Green? (Explained)

- Can You Sublimate on Canvas? (Yes You Can But…)

What is Sublimation Coating Spray?

Sublimation coating spray contains a specialized polymer resin that creates a coating designed to accept dispersed dye from sublimation inks. The spray bonds to the substrate you apply it to, forming a polymeric layer.

When you sublimate on the coated surface, the coating acts like a dye receptor. It absorbs and binds the dye from the ink so it permanently colors the coating.

This is what allows you to sublimate on materials that don’t normally work with sublimation.

Here are some key features and benefits of sublimation coating spray:

Sublimation coating sprays have been a game changer for dye sublimation printing. They allow you to customize and print full-color graphics on so many everyday items.

How to Apply Sublimation Coating Spray

Applying sublimation coating spray takes a bit of practice to master. Here is an overview of the complete process:

- Surface preparation – Clean the surface completely and remove any oil, dirt, or dust. Wipe down with alcohol if needed to remove residues.

- Masking – Cover any areas you don’t want to be coated using stencils, tape, or cardboard. Be precise with masking for clean results.

- Shake spray can – Shake the spray paint-style can vigorously for at least 60 seconds to fully mix the polymer resin.

- Apply spray – Holding the can 6 to 8 inches away, apply a smooth, light coat using a side-to-side sweeping motion. Work in a well-ventilated area.

- Dry – Allow the coating to fully dry and cure, usually at least 60 minutes between coats. Drying time may be longer with cooler temps or high humidity.

6. Apply additional coats – For best results, apply at least 2-4 light coats allowing ample drying time between each. Less is more with the spray.

7. Cure – Some coatings require a post-heating cure to fully crosslink. Follow the product instructions for proper curing.

8. Test print – Perform test prints with small transfers first to dial in your printer settings before printing the final transfers.

9. Sublimate – With your print settings optimized, you’re ready to sublimate on your coated blanks!

Taking the time to properly prep, coat, cure, and test will help you achieve beautiful, lasting results with sublimation coating spray.

Key Factors to Consider When Purchasing Sublimation Coating Spray

With so many sublimation coating sprays on the market, it can be difficult to know what to look for when making your purchasing decision.

Here are some of the most important factors to take into account:

1. Reputable Brand

Stick with well-known brands that specialize in coatings rather than generic products. Established companies like PolyAmerica and Joto have proven track records for performance and reliability.

Their products are less likely to clog spray heads or cause other issues.

2. Spray or Brush-On

Spray cans provide the easiest, most consistent application for beginners. Brush-on gels take more skill but allow you to coat specific areas and touch up spots. Consider your skill level and needs.

3. Drying Time

Faster drying times allow you to print and sublimate sooner after coating. Look for products that fully dry within 60 minutes or less under normal conditions. Quick dry formulas improve workflow.

4. Curing Requirements

Some coatings require a baking or heat-curing step after application which adds time and complexity. Opt for air dry formulas without curing for simplicity.

5. Coating Clarity

Clear glossy coatings typically produce the brightest most vivid prints. Colored or frosted tints can dampen color saturation.

6. Coverage

Calculate the coverage per can/bottle to determine if the amount is suitable for your production needs and budget.

7. Compatibility

Ensure the coating specifically works with your desired blanks like ceramic, cotton, wood, acrylic, etc. Read the specs closely.

Taking the time to carefully evaluate the different coating sprays using these criteria will help you select the best option for your specific sublimation needs and workflow. Test samples first whenever possible.

Best Sublimation Coating Sprays Currently Available

With the growing popularity of sublimation coating sprays, there are now many options on the market to choose from.

Here are some of the leading solutions that consistently receive high marks:

1. HTVRONT Sublimation Coating Spray

The HTVRONT Sublimation Coating Spray is an all-in-one coating designed to prepare surfaces for sublimation printing.

This spray contains a specialized polymer layer that adheres to substrates and bonds with dispersed dye from sublimation inks to allow for permanent, full-color prints.

It simply requires spraying a thin, even layer onto the desired surface and allowing it to fully dry before sublimation printing.

Advantages of using the HTVRONT spray:

2. NGOODIEZ Sublimation Coating Spray

NGOODIEZ Sublimation Coating Spray is a polymer-based spray coating designed to prep surfaces for dye sublimation printing. It comes in an aerosol can for quick, easy application onto substrates.

The NGOODIEZ spray provides an even layer of clear coating that dries in 5 minutes. It creates a receptive barrier that bonds with dispersed dyes from sublimation inks when heat-pressed.

This allows for permanent, full-color sublimation prints even on untreated surfaces like cotton, wood, slate, etc.

Some of the biggest advantages of using NGOODIEZ Sublimation Coating Spray include:

Tips for Using Sublimation Coating Spray on Different Surfaces

One of the best things about sublimation coating spray is the variety of surfaces you can use it on. Here are some of the most popular blank materials to coat and tips for success:

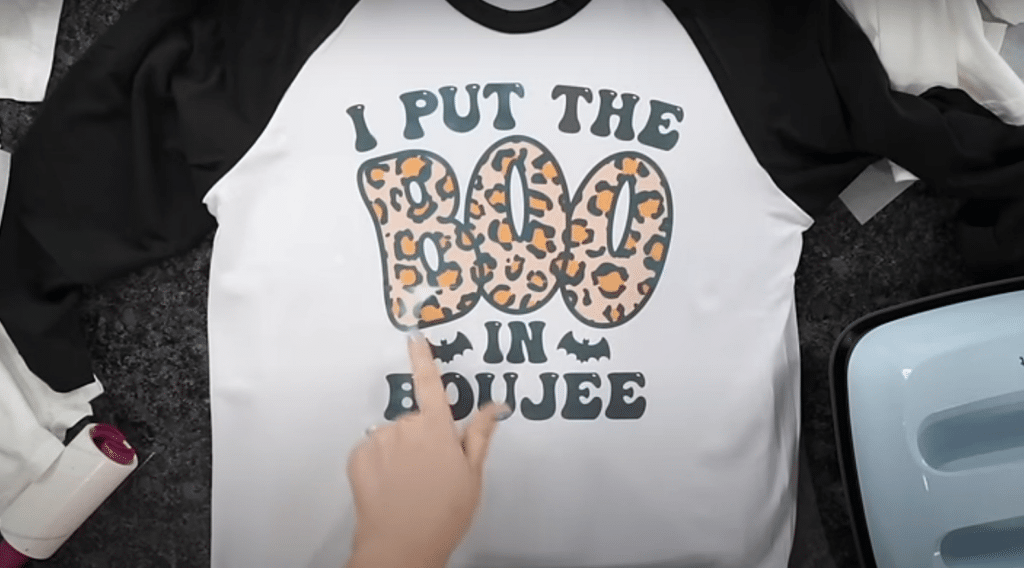

Cotton Apparel

- 100% cotton shirts, bags, hats, and other apparel are prime candidates for cotton sublimation.

- For shirts, spray just the front panel area where your design will go to save coating.

- Cotton tends to yield more muted colors vs. polyester but still looks great.

- Turn shirts inside out and wash them in cold water to maximize print longevity.

Ceramic Mugs

- Coating plain ceramic mugs allows full wrap-around photo mugs.

- Apply masking tape around the mug’s handle and bottom rim before spraying.

- Allow a full 72 hours drying time for thick ceramic coatings before sublimating.

- Hand wash coated mugs and don’t soak them to prevent the coating from softening over time.

Wooden Blanks

- Sublimate designs onto wood slices, cutting boards, coasters, plaques, and more.

- Use fine-grit sandpaper to prep and smooth the wood surface before applying the coating.

- Allow extra dry time for the coating to fully cure before sublimating onto porous wood.

- A sealing top coat after sublimating can add protection from moisture damage.

Canvas Fabric Shoes

- Coating canvas shoes opens up options for printing custom fabrics.

- Tape off rubber sole edges and laces to avoid getting coating on them.

- The fabric has more texture than other materials, so increased pressure may improve dye transfer.

- expect some hand/stiffness from the coating and print designs that don’t wrap under the feet.

Frequently Asked Questions

below are a few frequently asked questions:

How do you make your sublimation coating spray?

It is very difficult to make effective sublimation coating spray from scratch at home. You need very specific polymers, solvents, and additives to create a usable coating. Purchasing premade spray is highly recommended.

Which chemical is used for sublimation coating?

Most sublimation coatings use polymers and resins like acrylic, polyurethane or epoxy suspended in a solvent. The exact formulations are proprietary to each brand.

Wrapping Up

Sublimation coating spray opens up a whole new world of printable blanks and substrates with your dye sublimation printer.

With just a quick spray application, you can sublimate on wood, ceramics, cotton, acrylics, metals, and more.

While coated substrates don’t produce quite as vibrant colors as polyester, the results are very impressive.

So grab some blank mugs, sneakers, leather goods, or anything else you want to sublimate on. Coat, press and unlock the full potential of your printer!