Have you ever been in the middle of a heat press project, only to have your fuse blow, leaving you frustrated and unsure of what went wrong?

It’s a common issue that many heat press users face, and it can be frustrating to deal with. Dealing with a heat press that keeps blowing fuses can be a real headache.

But don’t worry,

In this article, we’ll explore ‘Why does my heat press keeps blowing fuse’, We’ll also provide some practical tips and preventive measures to help you stop the heat press fuse from blowing.

Keep reading to learn more!

you may also like:

- Can You Remove Sublimation Ink from Different Blanks?

- What Is Sublimation Glass? (Features & Process)

- Can You Mix Sublimation Ink Brands?

- Can You Sublimate on Burlap Products?

Why Does My Heat Press Keeps Blowing Fuse?

Below are a few reasons why your heat press keeps blowing the fuse:

1. Exceeding Wattage Capacity

One of the most common reasons why your heat press keeps blowing fuses is that you’re exceeding the wattage capacity of the circuit where your heat press is plugged in.

Heat presses are power-hungry machines, that consume a significant amount of electricity. If you plug them into a circuit that’s already overloaded with other appliances, the fuse is likely to trip as a safety measure.

When you exceed the wattage capacity of a circuit, it means that the total electrical load on that circuit is greater than what the circuit is designed to handle.

2. Faulty Wiring

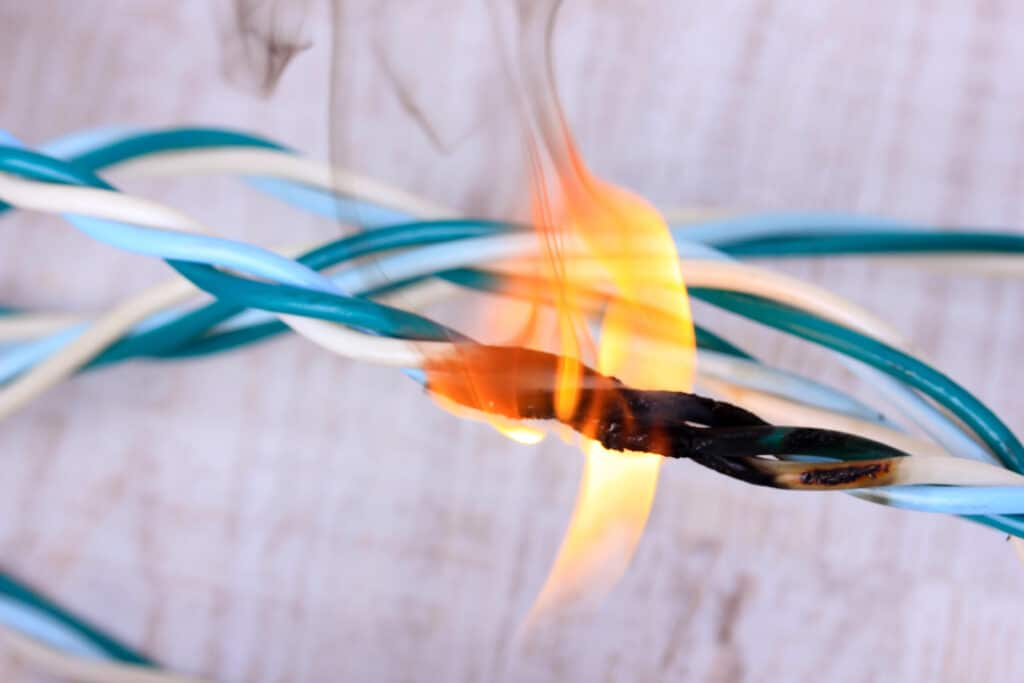

Internal wiring issues within the heat press itself can also cause a short circuit, leading to a blown fuse.

Over time, wires can become frayed, loose, or damaged, creating a potential electrical hazard. This can cause a sudden surge of current, tripping the fuse to prevent further damage.

Faulty wiring can occur due to several reasons, such as manufacturing defects, wear and tear, or even accidental physical damage.

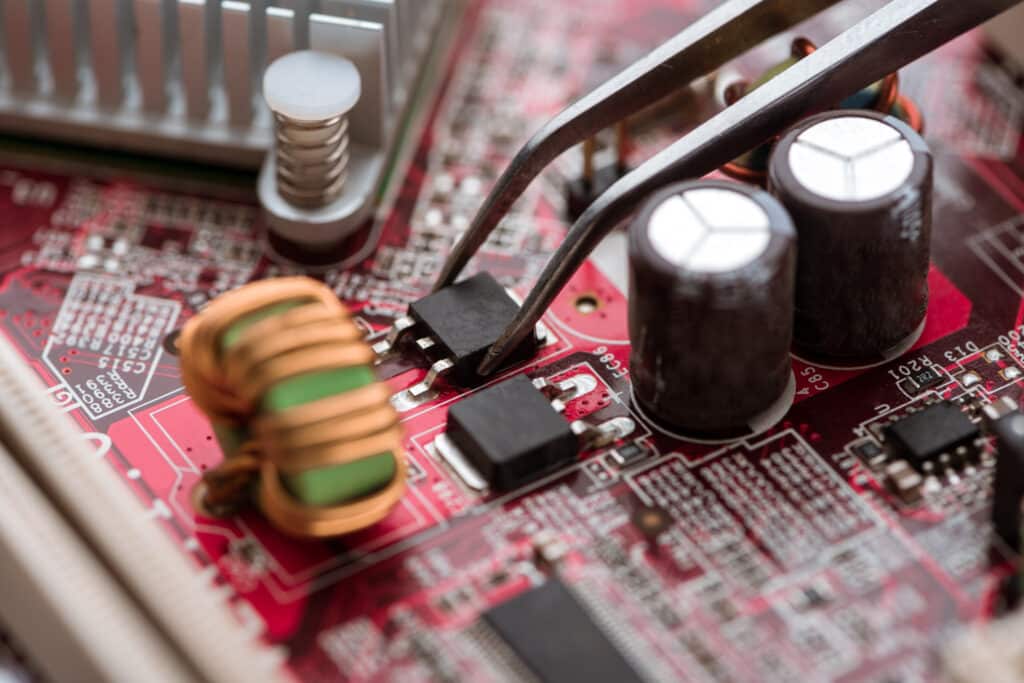

3. Malfunctioning Heating Element

The heating element is the heart of your heat-press, and if it malfunctions, it can draw more current than it’s designed for, causing the fuse to blow.

This can happen due to various reasons, such as manufacturing defects, wear and tear, or exposure to extreme temperatures.

The heating element is responsible for generating the heat necessary for your heat press to function correctly. It’s typically made of a resistive material, such as nichrome or ceramic, that heats up when an electric current passes through it.

4. Shorts or Leaks in the Element

Even if the heating element itself is functioning correctly, internal shorts or leaks within the element can cause a current surge, leading to a blown fuse. These shorts or leaks can occur due to damage, wear, or manufacturing defects.

A short circuit within the heating element can occur when the resistive material inside the element develops a low-resistance path, allowing electricity to flow more freely than intended.

Similarly, leaks within the heating element can also cause issues. If the insulating material surrounding the resistive element becomes compromised, it can create an electrical path to the ground, resulting in a short circuit or current leak.

5. Loose Connections

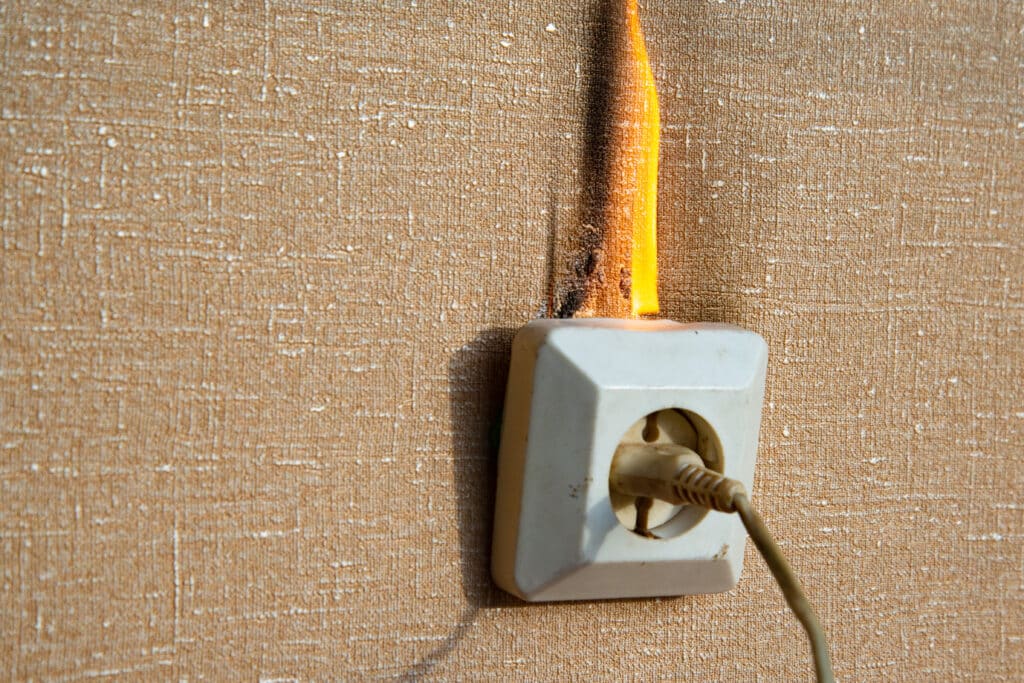

Loose or faulty connections within the heat press can create electrical sparks or resistance, leading to a blown fuse. These connections can become loose over time due to vibrations, heat, or improper installation.

Loose connections can occur at various points within the heat press, such as the power cord connection, terminal blocks, or even the connections between the heating element and the control circuitry.

When connections become loose, they can create electrical resistance, which can generate heat and potentially cause arcing or sparking.

6. Voltage Fluctuations

Inconsistent voltage in your power supply can sometimes cause sudden surges, tripping the fuse. This can be due to issues with the electrical grid, faulty wiring, or other external factors beyond your control.

Voltage fluctuations can occur due to various reasons, such as power outages, electrical storms, or issues with the local electrical infrastructure.

When the voltage supplied to your heat press fluctuates or spikes, it can cause an excessive current draw, leading to a blown fuse.

How to Stop the Heat Press Fuse from Blowing

Below are some preventive methods that you can use to stop the heat press from blowing the fuse:

1. Check the Circuit

The first step in preventing your heat press fuse from blowing is to ensure that your heat press is plugged into a circuit with sufficient capacity to handle its wattage.

When you plug your heat press into an overloaded circuit, it’s essentially putting too much demand on that circuit, which can cause the fuse or circuit breaker to trip as a safety measure.

To check the circuit capacity, you’ll need to determine the wattage requirements of your heat press. This information should be readily available in the user manual or on the product specifications.

2. Consult the Manual

Refer to your heat press’s user manual for troubleshooting tips and recommended fuse ratings. The manufacturer may provide specific instructions on how to handle blown fuses or other electrical issues.

User manuals are a valuable resource when it comes to understanding the proper operation and maintenance of your heat press. They often contain detailed information on troubleshooting common issues, including blown fuses.

In the user manual, you may find specific instructions on what to do if a fuse blows, such as the recommended fuse rating to use for replacement, or steps to check for potential causes like wiring issues or heating element problems.

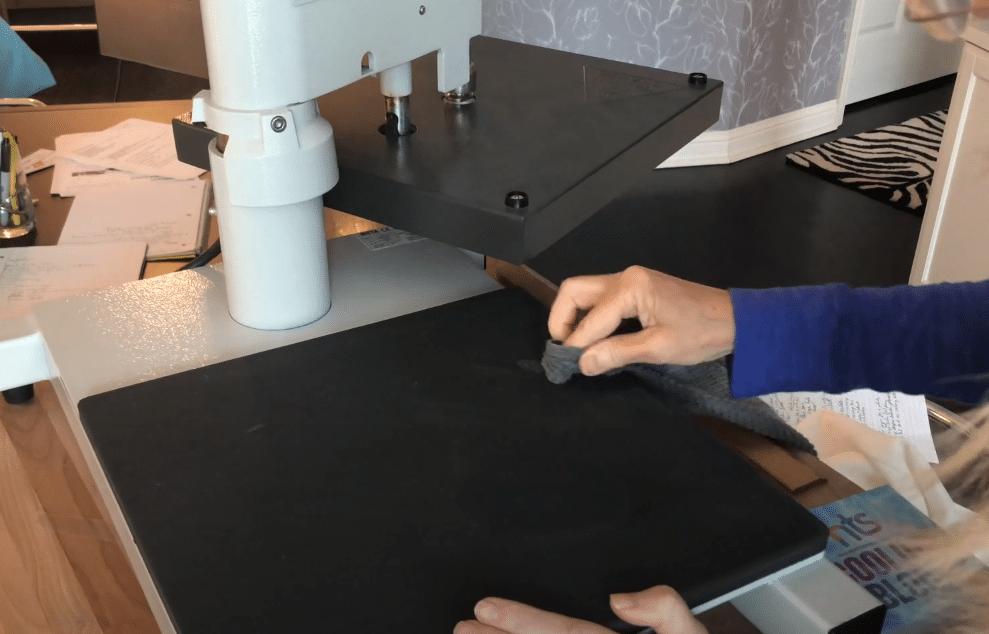

3. Visual Inspection

Conduct a visual inspection of your heat-press, looking for any visible signs of damage to the power cord, plug, or internal wiring. If you notice any frayed or damaged wires, it’s best to have them replaced by a professional.

A visual inspection is a simple yet effective way to identify potential issues that may be causing your heat press to blow fuses. Here are some steps to follow:

- Unplug the heat press from the power source and allow it to cool down completely before inspecting.

- Inspect the power cord for any signs of damage, such as fraying, cuts, or exposed wires.

- Check the plug for any signs of burn marks, melting, or loose prongs.

- If possible, remove any external panels or covers to access the internal wiring of the heat press.

- Carefully inspect the internal wiring for any signs of damage, such as fraying, discoloration, or loose connections.

- Check for any signs of overheating or burn marks on the wiring or components.

- Ensure that all connections are tight and secure.

- Look for any signs of moisture or corrosion, which can cause electrical issues.

4. Seek Professional Help

If you suspect a faulty heating element, internal wiring issues, or any other problems beyond your expertise, seek help from a qualified technician.

Attempting to repair these issues yourself can be dangerous and may cause further damage to your heat press.

While some basic troubleshooting and maintenance tasks can be performed by the heat press owner, certain issues require the expertise of a trained professional. These include problems with the heating element, internal wiring, or electrical components.

Frequently asked questions

Below are a few frequently asked questions:

Can High Resistance Burn a Fuse?

Yes, high resistance in an electrical circuit can cause excessive heat buildup, which can potentially burn or blow a fuse.

This is why it’s essential to ensure that all connections are tight and free from corrosion or damage.

Why Does Fuse Wire Melt on Heating?

The fuse wire is designed to melt or burn when subjected to excessive current flow, acting as a safety measure to prevent further damage to the electrical circuit.

This is a normal behavior of a fuse when it’s doing its job correctly.

Does a Fuse Depend on Current or Voltage?

Fuses are primarily designed to protect against excessive current flow, not voltage. The rating of a fuse is based on the maximum current it can safely handle before needing to be replaced.

Wrapping Up

Dealing with a heat press that keeps blowing fuses can be a frustrating experience, but by understanding the underlying causes and taking the proper precautions, you can avoid this issue and ensure the smooth operation of your heat press.

Throughout this article, we’ve explored various reasons why your heat press might be blowing fuses, such as overloading the circuit, faulty wiring, malfunctioning heating elements, shorts or leaks in the element, etc.

We’ve also provided practical tips and preventive measures to help you stop the fuse from blowing, including checking the circuit capacity, consulting the user manual, and conducting visual inspections.

Remember, your safety should always be the top priority when working with electrical equipment like a heat press.

If you’re unsure about the cause of the blown fuse or lack the necessary skills to fix it yourself, don’t hesitate to seek professional assistance.