Have you ever been in the middle of a heat press project, only to have the breaker trip, leaving you frustrated and unsure of what went wrong?

If this has happened to you, you’re not alone. Many heat press users face this issue, which can be caused by various factors.

In this article, we’ll explore ‘Why heat press keeps tripping breaker?’ and provide you with practical solutions to prevent it from happening again.

By understanding the root causes, you can take the necessary steps to ensure your heat press runs smoothly and efficiently, allowing you to focus on your creative projects without interruptions.

So, keep reading!

you may also like:

- Can You Sublimate On PVC? (Answered!)

- Can You Sublimate on Silicone? (Explained!)

- Butcher Paper vs Parchment Paper For Sublimation

- Can You Sublimate On Modal Fabric? (Yes, But..)

Why Heat Press Keeps Tripping Breaker?

Below are a few reasons why the heat press keeps tripping breaker:

1. Electrical Circuit Overload

One of the primary reasons your heat press might be tripping the breaker is an electrical circuit overload. Heat presses require a significant amount of power to operate, especially during the initial heating phase.

If your heat press is plugged into a circuit already overloaded with other appliances, the combined power draw might exceed the circuit’s capacity, causing the breaker to trip.

2. Heat Press Internal Malfunction

In some cases, internal components within the heat press itself, such as heating elements or control boards, might malfunction and draw excessive current, causing the breaker to trip.

This could be due to a manufacturing defect, wear and tear, or other issues. If you suspect an internal issue, it’s best to have your heat press inspected and serviced by a qualified technician or the manufacturer’s authorized repair center.

3. Ground Fault

Ground faults can occur due to various reasons, such as damaged insulation on the wiring, moisture or water exposure, or a faulty ground connection.

When a current leak occurs, it creates an alternate path for the electricity to flow, which can be dangerous if it comes into contact with a person or conductive surface.

4. Loose Connections

Loose connections anywhere in the electrical circuit, including the outlet, wiring, or even inside the heat press, can cause the machine to draw more current than it should. This can lead to the breaker tripping as a protective measure.

Loose connections can occur due to vibrations, wear and tear, or improper installation. When a connection is loose, it creates resistance in the electrical flow, which can generate heat and potentially cause arcing or sparking.

5. Blocked Airflow

Heat presses generate a significant amount of heat during operation, and proper airflow is crucial to prevent overheating.

If the airflow is blocked, whether by the press being too close to walls or other obstructions, it can cause the internal components to overheat, leading to the breaker tripping.

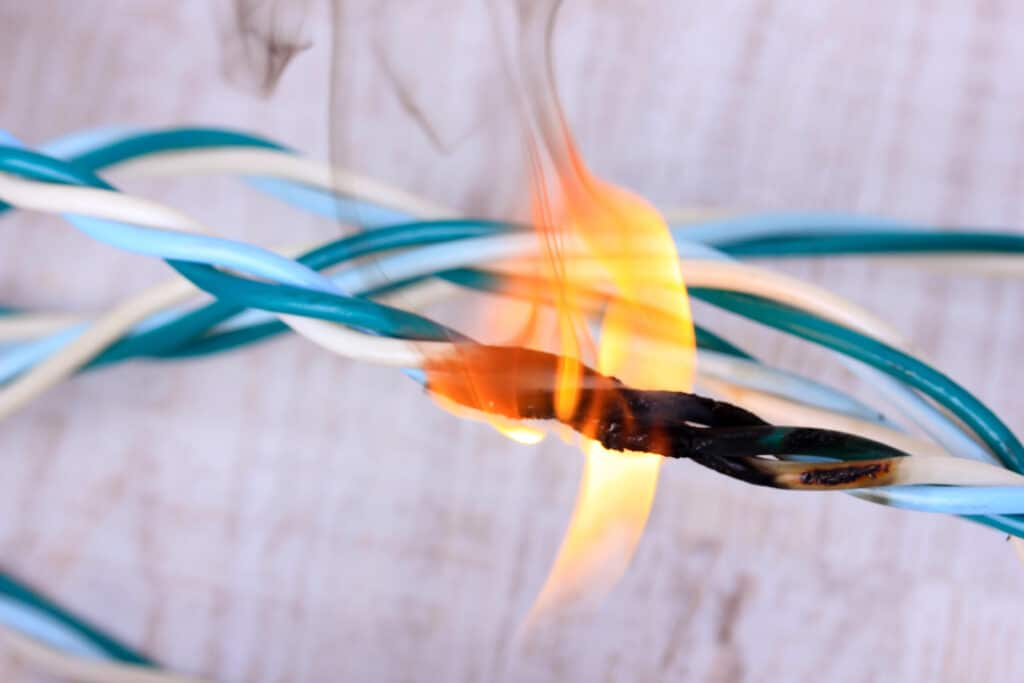

6. Short Circuit

A short circuit occurs when two hot wires come into direct contact with each other or with a neutral or ground wire. This can result in an excessive current flow in the electrical circuit, causing the breaker to trip as a safety measure.

Short circuits can occur due to various reasons, such as damaged wiring, loose connections, or a manufacturing defect.

7. Defective Circuit Breaker

In some cases, the issue might not be with the heat press itself but with the circuit breaker.

Over time, circuit breakers can wear out or become defective, making them unable to handle the current flowing through the circuit properly.

How to Prevent Heat Press from Tripping the Breaker

Below are a few prevention tips that you can use to prevent your heat press from tripping breaker:

1. Use a Dedicated Circuit

Ideally, your heat press should be plugged into a dedicated circuit with sufficient capacity to handle its power requirements.

This helps avoid overloading the circuit and ensures the press receives the necessary power for optimal operation.

2. Avoid Extension Cords

Whenever possible, avoid using extension cords with your heat press. Extension cords might not be rated for the appliance’s power draw and can pose safety hazards.

Using an extension cord can lead to several potential issues including voltage drop, overheating, tripping hazards, electrical overload, etc.

3. Inspect and Maintain Your Heat Press

Regular inspections and maintenance of your heat press can help identify and address potential issues before they cause problems.

Check for loose connections, worn-out components, or any signs of damage, and have them repaired or replaced as needed.

4. Keep the Heat Press Well-Ventilated

Ensure that your heat press has adequate ventilation and airflow. Keep it away from walls, curtains, or other obstructions that could restrict airflow and cause overheating.

If the heat press is not adequately ventilated, the internal components can overheat, leading to potential damage or even breaker tripping as a safety measure.

5. Hire a Professional Electrician

If you suspect wiring issues, faulty circuit breakers, or other electrical problems, it’s crucial to seek the help of a qualified electrician.

They can properly diagnose and repair any issues with your home’s electrical system or the heat press itself, ensuring safe and reliable operation.

6. Follow Manufacturer’s Guidelines

Always refer to your heat press’s user manual and follow the manufacturer’s guidelines for proper installation, operation, and maintenance. This can help prevent issues that could lead to tripping the breaker.

The user manual provided by the manufacturer is a valuable resource that contains important information specific to your heat press model.

7. Consider Upgrading Your Electrical System

If your home’s electrical system is outdated or undersized, it might be worth considering an upgrade to accommodate the power demands of modern appliances like a heat press.

Consult with a licensed electrician to assess your needs and make the necessary improvements.

How to Reset the Heat Press?

If the above solutions don’t help, resetting the device might be your last option. Follow these steps to reset your heat press:

- Turn off the heat press: Press the power button to turn off the heat press, or disconnect it from the outlet.

- Wait for a few minutes: Allow the heat press to cool down before proceeding.

- Find the reset button: Locate the reset button on the control panel or at the rear of the device, depending on your model.

- Press the reset button: Use a small, pointed object like a pen or paperclip to press and hold the reset button for a few seconds.

- Release the reset button: Release the reset button and wait a few seconds.

- Turn on the heat press again: Press the power button or plug the heat press back into the outlet to turn it on.

- Test the heat press: Set the temperature and time settings correctly, and press the heating element firmly against the material to test the heat press.

If the heat press still malfunctions or trips the breaker after resetting, refer to the user manual or contact the manufacturer for further assistance.

Watch the below video to deepen your understanding:

frequently asked questions

Below are a few frequently asked questions:

Why does my heat press keep blowing fuses?

If your heat press keeps blowing fuses, it could be due to a short circuit, overloading the circuit, or a faulty component within the heat press.

It’s essential to have it inspected and repaired by a professional to identify and address the root cause.

Why does my heater trip the breaker after a few minutes?

If your heater trips the breaker after a few minutes of operation, it could be due to an overload on the circuit, a malfunctioning heating element, or a wiring issue.

Check for proper ventilation, inspect the heating element, and consult an electrician if necessary.

Can a bad capacitor trip a breaker?

Yes, a bad capacitor in the heat press or other electrical appliances can cause a short circuit or draw excessive current, leading to the breaker tripping.

If you suspect a faulty capacitor, it’s best to have it inspected and replaced by a professional.

Wrapping Up

Dealing with a heat press that keeps tripping the breaker can be frustrating, but it’s essential to address the issue promptly to prevent potential safety hazards and ensure the longevity of your equipment.

By understanding the possible reasons and following the preventive measures outlined in this article, you can minimize the risk of breaker tripping and enjoy a smooth and uninterrupted heat press experience.

Remember, when it comes to electrical issues, safety should always be the top priority. If you’re unsure about any aspect of troubleshooting or repairs, don’t hesitate to seek professional assistance from a qualified electrician.

With proper maintenance and precautions, your heat press will continue to serve you reliably for years to come.