Are you interested in sublimation printing but struggling to get the bright, vibrant results you’re after?

Don’t worry, you’re not alone!

Sublimation is an awesome way to put long-lasting designs on all sorts of materials like clothes, mugs, and even metal. But it can take some practice to master the techniques.

In this article, we’re going to explore ‘How can I get better at sublimation’ that will level up your sublimation skills.

We’ll cover everything from choosing the right equipment and materials to perfecting your color management to developing a smooth workflow for consistent results.

So, keep on reading!

you may also like:

- Is Sublimation Printing Eco-Friendly?

- What Is A Sublimation Water Bottle? (Explained!)

- What Sublimation Items Sell Best? Top 10 Products

- How Much Should I Charge for Sublimation Shirts?

How Can I Get Better At Sublimation?

Below are a few tips to improve your sublimation skills:

1. Invest in Quality Equipment

The first step towards sublimation success is having the right tools for the job. Invest in a high-quality sublimation printer, heat press, and compatible inks.

Please don’t skimp on these essentials, as they can make a world of difference in the clarity and vibrancy of your prints.

Look for sublimation printers from reputable brands like Sawgrass or Epson, known for their advanced sublimation printing capabilities. Regarding heat presses, opt for swing-away or clamshell models that offer even heat distribution.

2. Understand Your Materials

Not all materials are created equal when it comes to sublimation. Different substrates, such as polyester, ceramics, and metals, have varying characteristics that can impact the final result.

Take the time to understand the nuances of each material and adjust your settings accordingly.

However, the fabric’s composition, weave, and coatings can influence color vibrancy and print quality. Experimenting with different polyester blends and fabric types can help you identify the ideal substrate for your specific projects.

3. Master Color Management

Color accuracy is crucial in sublimation printing. Invest in a good color management system and calibrate your equipment regularly.

This will ensure that the colors you see on your screen are accurately represented in your prints.

Color management involves several components, including monitor calibration, printer profiling, and software settings.

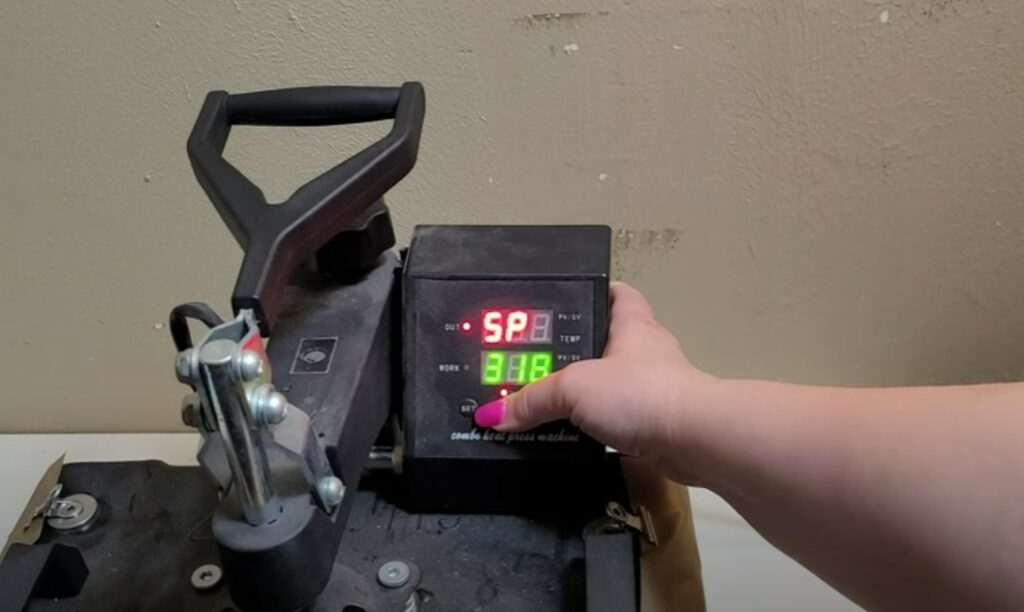

4. Experiment with Heat and Pressure

Heat and pressure are the dynamic duo of sublimation printing. Too much or too little of either can lead to subpar results.

Experiment with different temperature and pressure settings to find the sweet spot for each material and design.

The ideal heat and pressure settings can vary depending on the substrate, the complexity of the design, and even the ambient conditions in your workspace.

5. Use High-Quality Images

The adage “garbage in, garbage out” holds in sublimation printing. Start with high-resolution, high-quality images and designs for the best possible outcomes.

When working with photographic images, aim for a minimum resolution of 300 dpi (dots per inch) or higher.

High-resolution images ensure sharp details, smooth gradients, and minimal pixelation or jagged edges when transferred to the substrate.

6. Pre-treat Your Substrates

Certain materials may benefit from pre-treatment before sublimation. This could involve applying a coating or spray to enhance ink adhesion or removing any contaminants that could interfere with the printing process.

For example, some ceramics and metals may require a specialized polymer coating or primer to provide a surface for the sublimation dyes to bond with.

These coatings create a receptive layer that helps the gaseous dye molecules penetrate and adhere to the substrate during the sublimation process.

7. Keep Your Equipment Clean

A clean work environment and well-maintained equipment are essential for consistent, high-quality results.

Regularly clean your printer, heat press, and other tools to prevent dust, lint, or ink buildup from compromising your prints.

Start by keeping your workspace free from clutter, dust, and debris. Use lint-free cloths or compressed air to remove any accumulated dust or fibers from your printer, heat press, and work surfaces.

8. Stay Up-to-Date

The world of sublimation printing is constantly evolving, with new techniques, materials, and equipment being introduced regularly.

Stay informed about the latest advancements and trends by following industry blogs, attending workshops, or joining online communities.

Staying up-to-date with the latest developments in sublimation printing can provide you with valuable insights and knowledge that can help improve your craft.

9. Practice, Practice, Practice

Like any skill, sublimation printing takes practice. Don’t be discouraged by initial setbacks or imperfect results. Keep experimenting and refining your techniques until you achieve the desired outcomes.

One of the best ways to practice is by starting with small, inexpensive projects. Try sublimating on coasters, keychains, or ceramic tiles before moving on to larger or more complex substrates.

This allows you to experiment with different settings, designs, and techniques without the risk of wasting valuable resources or materials.

10. Develop a Consistent Workflow

Consistency is key in sublimation printing. Develop a standardized workflow that covers everything from image preparation to post-processing.

This will help you achieve repeatable results and streamline your production process.

Begin by establishing a set of best practices for image preparation. This might include guidelines for file formats, color modes, resolution requirements, and any necessary image adjustments or enhancements.

11. Document Your Process

Keep detailed records of your settings, materials, and techniques for each project. This documentation will serve as a valuable reference and help you troubleshoot any issues that may arise.

Create a dedicated log or database where you can record all the relevant details for each sublimation project.

This might include information such as the substrate type, brand, and composition, as well as the specific heat press settings (temperature, pressure, and dwell time) used for that particular material.

12. Embrace Continuous Learning

Sublimation printing is an ever-evolving art form. Embrace a mindset of continuous learning and never stop exploring new techniques, materials, and design approaches.

Stay up-to-date with the latest industry trends and advancements by regularly reading trade publications, attending workshops or webinars, and networking with other professionals in the field.

New materials, inks, or equipment are constantly being introduced, and staying informed can give you a competitive edge and open up new creative possibilities.

13. Have Fun!

Last but not least, remember to have fun with your craft! Sublimation printing is a creative outlet that allows you to transform ordinary objects into works of art.

Embrace the joy of the process, and let your passion for creating shine through in your work. Don’t get bogged down by the technical aspects of the pursuit of perfection.

While mastering the techniques and best practices is important, maintaining a sense of playfulness and experimentation can lead to unexpected and delightful results.

Frequently asked questions

Below are a few frequently asked questions to deepen your understanding:

How can you improve the sublimation process?

To improve the sublimation process, focus on investing in quality equipment, understanding your materials, mastering color management, experimenting with heat and pressure settings, using high-quality images, pre-treating substrates, keeping your equipment clean, etc.

How do I get the best color for sublimation?

To achieve the best color results in sublimation printing, it’s essential to invest in a high-quality color management system and calibrate your equipment regularly.

Additionally, use high-resolution, high-quality images and designs, and experiment with different temperature and pressure settings to find the optimal combination for your specific materials and designs.

What are the disadvantages of sublimation?

While sublimation printing offers many advantages, such as vibrant colors and long-lasting results, it also has a few drawbacks.

These include limited substrate compatibility, initial investment

learning curve, longer production times, etc.

Wrapping Up

Sublimation printing is a rewarding and creative endeavor that can yield stunning results with the right knowledge, skills, and dedication.

By following the tips outlined in this article, you’ll be well on your way to mastering this versatile technique and producing high-quality, vibrant prints that will leave a lasting impression.

Remember, the key to success lies in continuous practice, experimentation, and a willingness to learn and adapt. Embrace the journey, have fun with the process, and let your creativity soar.

With perseverance and a commitment to excellence, you’ll soon be producing sublimation masterpieces that will set you apart from the competition.